Section 6: Surface Finishes

Anchor: #i1010161Overview

The surface finishes of elements such as bridges, walls, posts, and pavement have a great influence on the visual character of the landscape scene and should be considered carefully during the design process. Special finishes may be used on virtually any structure or roadside element as long as its function is not impaired. Generally, special finishes used on any item considered an obstruction should seek to highlight the presence of the object rather than blend it into the background.

All surfaces are perceived by a combination of their color, texture, and pattern. These combinations are, in turn, modified by scale and distance.

Anchor: #i1010180Color

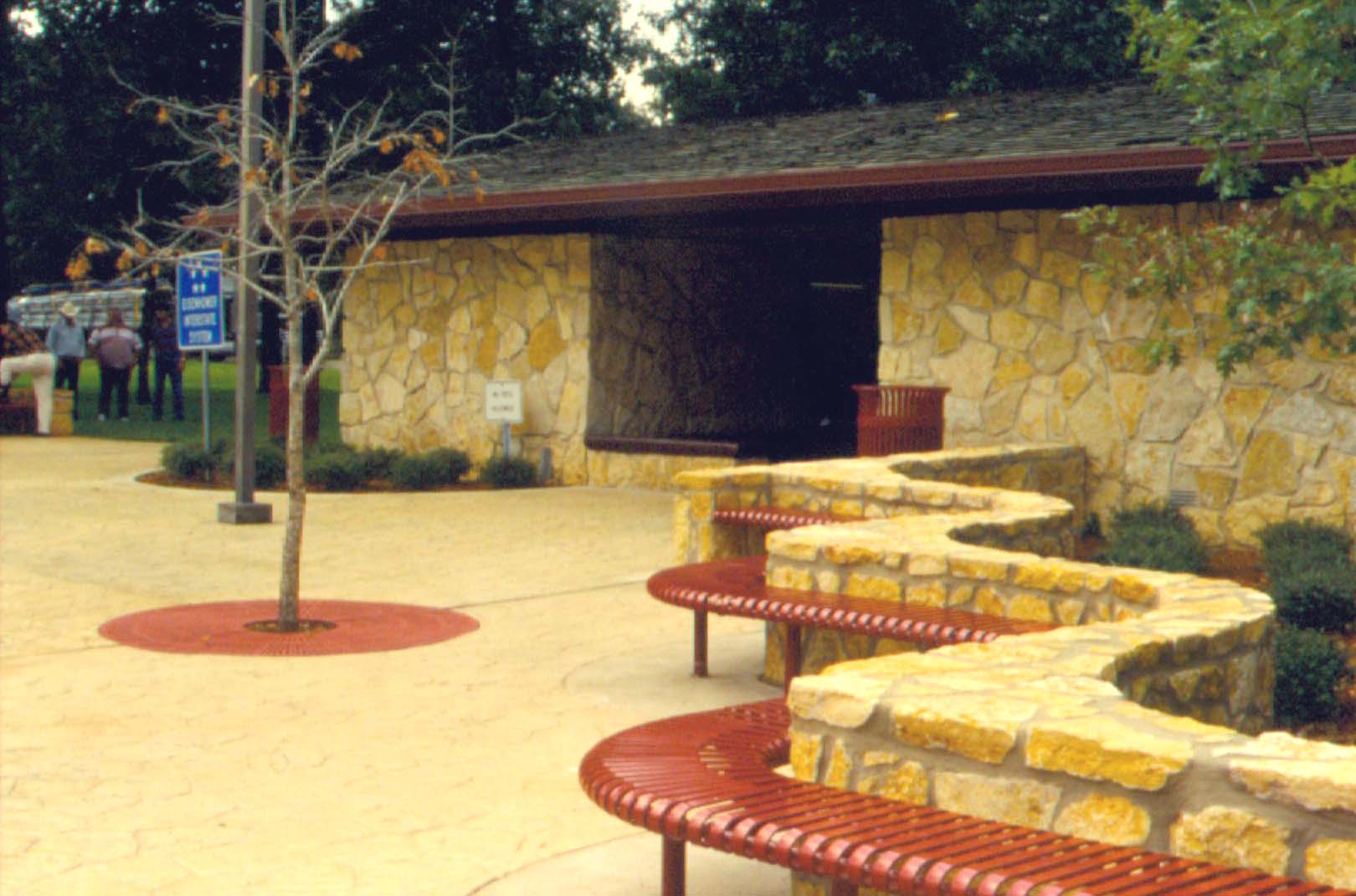

Color plays a principal role in our ability to make sense of the landscape. The various highlights and contrasts of the scene we see enable us to readily distinguish elements from one another and to pick those that are most important to us at the moment. In this regard, color is an important element in the roadway. It should be considered as a tool to improve driver perception and therefore the safety of the roadway in addition to its aesthetic value, as shown in Figure 4-30.

Figure 4-30. Coordinated colors and appropriate graphics can enhance entrances into communities.

Choosing colors. The colors selected for a transportation facility should be suitable for the intended purpose. That is, colors should help increase the safety and ease of use of the facility as well as increasing the visual appeal. Some basic guidelines that can be followed to aid in making color selections are:

- Anchor: #ANAMEWPC

- Link elements widely separated by space. Colors used to link elements should be similar in shade and brightness (see Figure 4-31). Anchor: #KXEGTXKF

- Highlight certain elements to attract attention. Highlighted elements need colors brighter than those round them (see Figure 4-32). Anchor: #CKHURIAN

- Reduce the visual prominence of an element. Muted colors that reflect less light than other elements near or behind them will attract less attention. Anchor: #MBXVWJMY

- Contrast one element with another to enable quick identification. High-contrast colors used close to one another will attract attention to that spot.

Figure 4-31. Colors can visually unite different structures in a scene.

Figure 4-32. Bright colors create interest with contrast and attract attention to the area.

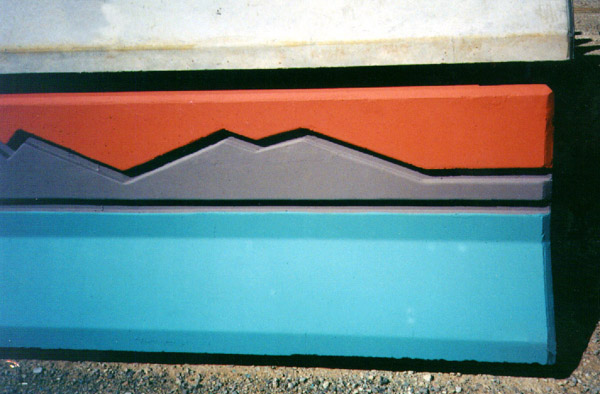

The Effect of Distance on Color. Atmospheric conditions can reduce or enhance the intensity of colors. Where transportation facilities are concerned, the effect of most atmospheric conditions (haze, fog, rain) is to wash out the intensity and brightness of the actual color. Colors that appear bright or very intense in close proximity will appear much grayer in actual field conditions. Colors that are intended to be distinguished at long distances should generally be brighter than one would normally select for objects intended to be viewed from close range to compensate for this phenomenon. Figures 4-33 and 4-34 show examples of bright colors used along the roadway.

Narrow lines of color will quickly be lost unless they are very bright. Color lines only a few inches in width, meant to accent an element, will not be visible for long distances.

Figure 4-33. Concrete traffic barriers are easily molded to reflect local themes. Bright colors are necessary for visibility at long distances.

Figure 4-34. Bright colors tend to appear muted in light-saturated roadways.

The Effects of Scale on Color. The size of the roadway creates a relationship between color, texture, pattern, and scale that should be noted. In order to be appreciated, a color, pattern, or texture must be visible. The size of treated areas should not be so small as to have little visual effect. Inversely, too much of a single treatment can become boring or overpowering. There are no hard-and-fast rules to determine when these lines have been crossed but generally, special treatments should accent rather than dominate a landscape scene.

Anchor: #i1010288Texture

The material that provides the greatest flexibility in selecting texture is Portland Cement concrete. Textures on concrete may be achieved through the use of form-liners, sandblasting, or washing to expose the integral aggregate. The moldability of concrete allows unique patterns to be included in the design at a reasonable cost.

Choosing textures. Textures are most visually effective where traffic speeds are slower as at controlled intersections or where structures are close to the travel lane. Textures should be rougher if they are to be seen from longer distances. Rougher textures create more shadows on their surfaces and so create a high contrast with the sunlit areas of the surface, thereby providing a more visually prominent surface. Figures 4-35 and 4-36 show effects of distance on texture appearance.

Figure 4-35. Deep shadow-lines increase the distance at which texture can be perceived.

Figure 4-36. Coarse textures appear relatively smooth past a few hundred feet.

Textures on horizontal surfaces (pavements) will not be very prominent from the driver’s perspective unless they are very coarse or very near the driving lanes. Textures on pavement may be used to highlight different use areas such as pedestrian ways, bike lanes, and important decision points for handicapped persons.

Anchor: #i1010330Pattern

Patterns are another method of adding visual interest to an element or scene. These are most commonly found in the modular patterns of retaining walls where the shape of the panel provides the pattern. These decorative patterns are very successful at adding interest to otherwise plain surfaces (see Figures 4-37 through 4-39).

Ideally, the patterns should be coordinated through a corridor. This does not mean that all wall patterns should be the same. In some cases the patterns may help distinguish a particular site from others, avoiding monotony and creating interest. On the other hand, too many patterns in a small area can create visual confusion. If varied patterns are desired, a good rule of thumb is to limit any one view to only two different patterns.

Figure 4-37. The smooth, strong line of the cap is a good contrast to the angular lines of the panels in this wall.

Figure 4-38. This wall cap steps down with the panels and adds interest to the wall.

Figure 4-39. Plant material may be incorporated with a pattern to add interest and soften visual impact of a wall.

Anchor: #i1010377Special Finish Options

Special finish options vary according to the type of structure and surface to be treated. Figure 4-39 shows the use of a form liner to create a special finish. The most common structural material used in the roadway is concrete but special finishes have also been used on asphalt surfaces.

Figure 4-40. Form liners incorporated with architectural details create interesting patterns.

The suitability of any option must be considered in relation to the climate and other factors affecting the durability of the finish. Visiting sites where proposed finishes have been used is a good way the assess the suitability of an option. It is strongly recommended that samples of surface finishes be constructed to gauge the effects of the color selection and to establish proper application procedures. Ideally, these samples should be near the site so that the sample can be judged in the same quality of light as when it will be finally applied. The samples should be adequate in size to accurately determine the effects of the finish both near and far from the surface. In some cases, sample sizes ten feet square or greater may be required.

Finishes may be grouped based on whether they are to be applied to vertical surfaces or horizontal surfaces surface.

Anchor: #i1010414Vertical Surfaces

Special finish options for vertical surfaces include:

- Anchor: #CNEYQOJR

- form liners Anchor: #QXJKIBEL

- sandblasting Anchor: #XBWFAAVP

- exposed aggregate Anchor: #GEVUKQDI

- pigmented coatings Anchor: #YOXCGIXS

- integral dyes Anchor: #TKBFGWHU

- concrete coatings Anchor: #YMLVSUFE

- architectural veneers Anchor: #HXNJALPL

- modular structural units

Form Liners. Form liners are widely used and very effective at introducing texture contrasts to concrete structures (see Figure 4-34). Common form liner patterns include a raised or indented vertical pattern but other patterns such as brick and stone are also available (see Figure 4-40). Strong vertically oriented textures will tend to emphasize the height of structures while horizontal textures will de-emphasize height and highlight the structure’s linear character.

The choice of pattern may be determined by looking for visual clues from the area in which the structure is located. A heavily developed urban area may suggest a formal architectural pattern. Rural areas or locations with prominent natural features may warrant the use of form liner patterns suggestive of local native materials.

Figure 4-41. Form liners come in a wide array of patterns. This wall uses a plastic form for a stone pattern.

Sandblasting. Sandblasting has been used on bridge columns and abutments as a relatively inexpensive method of adding textural interest. Sandblasting removes the flat, cured finish and imparts a softer appearance to the structure. These textures will not be visible at long distances since sandblasting only affects a shallow depth of the surface. Consequently, this technique is best used where traffic speeds are lower and the structures are near the travel lane.

Sandblasting entire structures may make the edges of the structures less distinct and blended into the background. A band of untreated surface at the edges of the structure will prevent this and make the texture contrast more visually effective.

Color variation in cement and aggregate may result in different effects, even on the same structure. If sandblasting is to be used, specify that aggregate sources and cement rates remain the same in the areas to be treated.

Exposed Aggregate. Exposed aggregate finishes have been used in the past and they provide a durable finish that is usually more prominent than sandblasting but not as heavy as form liner finishes. The quality of the finish is highly variable, depending on the quality of the aggregate, cement content and the amount of cement removed from the surface. This last factor is very difficult to control and can result in a high degree of variation. If too much surface material is removed, aggregate may be dislodged, resulting in a pitted surface.

These factors have led to a decline in the usage of this technique. The best areas for this option are probably small areas where the number of washing operators is fewer and increased quality control is possible (see Figure 4-42).

Figure 4-42. Exposed aggregate may be used on vertical columns but the texture will not be apparent from any great distance.

Pigmented Coatings (Paints and Stains). Pigmented coatings are a relatively inexpensive method of adding visual interest to structures (see Figure 4-43). Paints have proven to be less durable than stains, requiring reapplication due to flaking, and are not recommended for concrete structures. Acrylic stains have proven to be much more long-lived in concrete applications and are available in a wide range of colors.

Pigment coatings such as stains are highly affected by the quality of the surface before application. Concrete surfaces must be completely and properly cured to avoid unsightly salt-streaking problems. Surface imperfections due to damage or to inadequate vibration during pouring will be clearly visible once the stain is applied.

Figure 4-43. Pigmented coatings and sealers may be used on vertical as well as horizontal surfaces.

Integral Dyes. Integral dyes color the entire quantity of concrete used in the structure. Their advantage is that later damage to the surface will be less obtrusive since the pigment extends throughout the pour. This may be less true for old surfaces that have become weathered.

For large structures such as bridge components, integral dyes may not be feasible due to the cost of the dye and given the fact that much of the dye is wasted in the interior of the structure where it will not be seen. In addition, variation in the quality of cement can result in different shades of color for the same amount of dye. This makes matching earlier pours very difficult when adding new sections or repairing existing damaged areas.

The best use of integral dyes is in less massive, thinner concrete structures such as paving where quality control is easier and there is less likelihood of variation in the cement.

Concrete Coatings. Concrete coatings are thin applications of masonry quality cements that have been pigmented with color (see Figure 4-44). Depending on the specific proprietary method, substrates of reinforcing meshes may be used. A wide variety of texture effects may be added prior to the cement setting up. Some applications include removable templates that leave very realistic representations of brick, tile, and stone finishes.

Figure 4-44. Concrete with latex additives may be sprayed on vertical or horizontal surfaces. Patterns may be achieved with templates.

These coatings have been widely used in commercial projects and their use in highway applications has been limited. The durability of the coatings appears adequate for many applications since they are composed of cement. However, since the surface finish usually has a stucco-like texture, pores and irregular surfaces may catch dust or hold moisture, resulting in mildew and staining.

Specific applications within highway design are yet to be determined but this technology may have a role in retrofitting existing structures for aesthetic goals. They may be applied to horizontal as well as vertical surfaces and have been used on driving and pedestrian surfaces in light-duty residential and commercial applications.

Architectural Veneers. Non-structural veneers of various materials may be installed over other structures such as walls, abutments, columns, or riprap. The veneers may be stone, modular concrete pavers, or brick, and in some cases, tile. Veneers may be useful in creating a visual link between unconnected elements such as bridges by retrofitting some portions of the surfaces with the same material. Veneers of local materials from the natural environment of the area can also relate the structure to the environment and highlight special areas, as shown in Figure 4-45.

The process of selection of a suitable veneer follows the same procedures as for any other finish. Local preferences should be considered and clues can be gathered from the surrounding architecture and environment and balanced with the issues of cost, maintenance, and safety.

Figure 4-45. Local materials may be used as veneers to improve visual connection to the surrounding context.

Modular Structural Units. Modular units are most prominent in the use of pre-cast panel, Retained Earth Walls (see Figure 4-46). A smaller unit scale is found in Modular Block retaining wall systems (see Figure 4-47). These systems impart patterns to wall surfaces that provide visual interest and help prevent large surfaces from becoming oppressively monotonous.

Figure 4-46. Standard retained-earth walls are available in a range of finish options.

Figure 4-47. Modular concrete block walls come in a variety of finishes and generally provide a coarse-textured surface.

The patterns provided by these systems can result from two components: the shape of the modular unit and the pattern created by the arrangement of different colored or textured units (see Figure 4-48). The scale of the structure and the type of unit affect the decision to add pattern in this way. Generally, larger structures require larger units and smaller structures need smaller units.

Figure 4-48. Concrete masonry units come in a wide variety of patterns and colors. Combinations of units create broad patterns.

Anchor: #i1010650Horizontal Surfaces

Horizontal paved surfaces suitable for special finishes include sidewalks, pedestrian crossings, paved medians, traffic control islands, and riprap. The finishes described below are often pedestrian-oriented (excepting riprap) but may also be suitable wherever slower traffic speeds allow their visual impact to be appreciated.

Special finish options for horizontal surfaces include:

- Anchor: #QHQHWGSD

- scoring Anchor: #YBRJEDTR

- patterned concrete Anchor: #UXPQCBMQ

- concrete coatings Anchor: #ENWYVSXF

- concrete finishing techniques Anchor: #ABEDKUDN

- pigmented coatings Anchor: #VRUVIHYU

- concrete dyes Anchor: #MVABNOBL

- modular paving units

Scoring. Scoring is simply using a jointing tool or saw to score the surface of concrete paving to create a pattern. These may be regularly spaced parallel lines, cross-hatched patterns or even randomly-spaced designs. A great deal of visual texture can be added to plain concrete by simply adding a well conceived scoring pattern.

Scoring the surface in a linear pattern is probably the least expensive means of adding texture. Likewise, there are few disadvantages to scoring a concrete surface. Scored patterns act as a network of control joints which help control thermal cracks.

Patterned Concrete. Similar to scoring, patterning concrete uses pre-fabricated dies to impress patterns into partially cured concrete (see Figure 4-49). Color may be added with integral dyes but most frequently is accomplished with a dry-shake method of applying surface dyes. The range of patterns available is quite large and varies with the manufacturer. Compare Figure 4-48 to Figure 4-50 to see different patterns in use.

Figure 4-49. Metal stamps are used to impress a pattern into wet concrete. Brick patterns work well in pedestrian areas.

Figure 4-50. Patterned concrete comes in a variety of styles.

This technique may be used on any horizontal or slightly sloped surface (see Figure 4-51). Its advantage is its durability when subjected to vehicular traffic, its relative ease of installation, and its reasonable cost.

The process of selecting a suitable pattern and color follows the same procedures as for any other finish. Local preferences should be considered and clues can be gathered from the surrounding architecture and environment and balanced with the issues of cost, maintenance, and safety. In addition, special attention should be given to the roughness of texture of the pattern since some patterns impart deep impressions. Pattern texture must be evaluated for its impact on bicycles, walking assistance devices, wheelchairs, strollers, and its potential to trip elderly or very young users (see Figure 4-52).

Figure 4-51. Concrete can be used to form patterns to accent and complement existing structures.

Figure 4-52. Patterns of impressed asphalt pavements need to be evaluated for impact on potential use.

Concrete Coatings. The same concrete coatings used for vertical surfaces are generally appropriate for horizontal surfaces (see Figures 4-44 and 4-53).

Figure 4-53. Sprayed textures can be customized for special applications.

Concrete Finishing Techniques. A variety of textures can be applied to concrete surface through the finishing process. As long as the surface roughness is adequate to provide safety for the user, different troweling techniques can be used to add variety. When troweling is combined with scoring, very pleasing effects can be achieved.

Common finishing techniques for plain concrete surfaces include broom textures over steel trowel finish, wood float finishes, and magnesium float finishes. Each of these offers a slightly different texture finish that may be used alone or in combination with others. Exposed aggregate, as discussed for vertical surfaces, (see Figure 4-54) has been widely used as a pedestrian walk finish but the slick surface of this material when wet often leads to dangerous conditions, especially on sloped walkways.

Figure 4-54. The fine texture of exposed aggregate will become secondary to its color over even short distances, and its surface may become slippery when wet.

Pigmented Coatings (Paints and Stains). Paints and stains may form a slick surface when wet and should be applied over rough textures if chosen for areas used by vehicles or pedestrians (see Figure 4-43). (See Pigmented Coatings under vertical surfaces.)

Concrete Dyes. Color may be added to concrete paving with integral dyes but care should be taken when using this technique. (See Integral Dyes under vertical surfaces.) A more commonly used technique is the application of surface dyes during the curing and finishing processes. This technique is reasonable in cost and the results are much more predictable than with integral dyes. In either case, the experience of the contractor will be a major factor.

The process of color selection for paved surfaces is discussed in the Color subsection above. Using color in paved surfaces, especially in pedestrian areas, has specific benefits. Color can reduce glare, improving the visual character and safety of intersections. Color can also provide a clear distinction between pedestrian and vehicular surfaces, adding clarity and, again, improving safety in a critical zone.

Modular Paving Units. Modular paving units such as bricks and concrete pavers have proven to be both a durable and cost efficient paving material. Depending on the specific character of the units themselves, each has been used in both vehicular and pedestrian applications. Pavers have commonly been used in pedestrian areas and raised medians. Applications may include pavers used as banding or edging in otherwise typical concrete flatwork (see Figures 4-55 through 4-58).

Figure 4-55. “Before” picture of riprap at a bridge abutment. See Figure 4-56 for an “after” photo.

Figure 4-56. Pavers added to riprap brighten this intersection and include a graphic that reflects local character in this “after” shot of the bridge abutment shown in Figure 4-55.

Figure 4-57. Concrete pavers are available in a wide variety of colors and are well suited for narrow islands.

Figure 4-58. Concrete pavers easily introduce patterns into medians.

The advantage of flexible paving units is that access to subsurface utilities and repair is easier than with poured-in-place concrete and the units can be salvaged for use in other areas. The biggest disadvantage is the susceptibility to deformation under vehicular traffic, especially heavy trucks. This problem can be solved by making sure that the paving foundation is adequate to meet the traffic loads.

The surface texture of the units should be selected to meet the requirements of safety for pedestrians and vehicles if the units will be part of the traveled way. Sizes and colors should be selected based on issues discussed in the Color subsection above. Colors should be selected that make a clear distinction between pedestrian and vehicular surfaces.