Chapter 2: Guidelines for Treatment Selection

Anchor: #i999846Section 1: Seal Coats as a Preventive Maintenance Technique

Anchor: #i999851General

TxDOT has had a formal preventive maintenance program since 1987. Seal coats are used extensively as a preventive maintenance technique for bituminous pavements throughout Texas. While routine maintenance can be characterized as a reactive process in which immediate repairs are made to existing distress, preventive maintenance treatments help to preserve a pavement and extend its useful performance life. It is desirable in Texas to place seal coats on a 6 to 8 year cycle, but this is not always possible due to funding constraints.

The process for selecting pavements to receive seal coats will vary among the districts. In general, the process starts with maintenance section supervisors because they are most familiar with the roads in the section and inspect them often. They are also aware of the resurfacing and maintenance history of a roadway. The maintenance section supervisor generally prepares a list of candidate projects, and the list is reviewed and modified as appropriate by the area engineer before being submitted to the district office. Before the final selection is made by district staff, it is recommended that a designated person from the district office travel the roads to ensure they are good seal coat candidates.

Seal coats provide no additional structure to an existing pavement, so pavements that are structurally deficient are not candidates for seal coats. In addition, because wide cracks or cracks experiencing large movements are expected to reflect through the seal coat, pavements with extensive amounts of distress are generally not good candidates for a preventive maintenance treatment. There is, however, still a considerable amount of seal coat applied as a Band Aid to hold the pavement for a few years until reconstruction or rehabilitation can be funded.

In many cases, spot base repair, edge repair, crack sealing, strip/spot seal coat, or level-up work may be required to make an existing pavement ready to receive a seal coat and to maximize the life of the pavement.

Factors that can affect the decision to use a seal coat as a maintenance treatment include the following:

- Anchor: #QBKNALDP

- condition of the existing pavement Anchor: #CTLYVXNH

- effectiveness of a seal coat in addressing the existing pavement deficiencies Anchor: #IRSDGCQH

- cost of the seal coat compared to other treatments Anchor: #CKQCPDWN

- traffic volume Anchor: #FFCFPQLA

- percent truck traffic Anchor: #ACMDHPAE

- repairs needed prior to the seal coat.

Current PMIS (Pavement Management Information System) data can aid in assessing the condition of the existing pavement. The PMIS is an automated system for storing, retrieving, analyzing, and reporting pavement condition information. It can be used to retrieve and analyze pavement information to compare maintenance and rehabilitation treatment alternatives, monitor current pavement conditions, and estimate total pavement needs.

PMIS may be used to describe current pavement condition and trends, locate areas with problems, identify types of problems, and estimate general preventive maintenance and rehabilitation needs. PMIS data include the following:�

- Anchor: #KSCVAOCK

- distresses� Anchor: #UTQYYNHC

- rut� Anchor: #LMUMGSXB

- ride� Anchor: #SVCLICEE

- last surface date Anchor: #LKLXMJSN

- maintenance cost per mile.

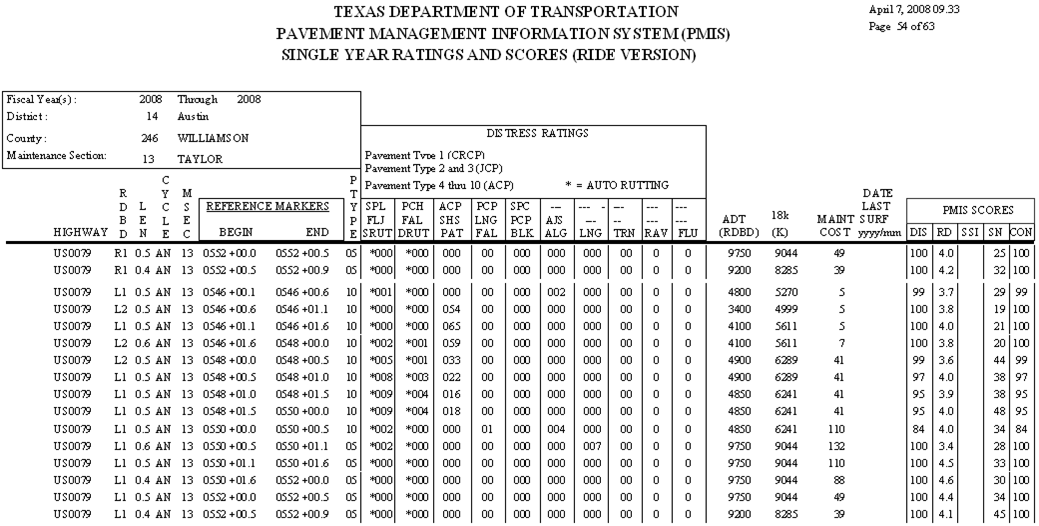

Figure 2-1. Sample PMIS Report.

Distresses shown in Figure 2-1 in the sample PMIS report are decoded as follows:�

- Anchor: #AYUQSTSH

- SRUT- shallow rutting (0.25- 0.49 inches deep), percent of wheelpath length� Anchor: #NGFNKOJW

- DRUT - deep rutting (0.50 to 0.99 inches deep), percent of wheelpath length� Anchor: #YRMSKKLI

- PAT - patching, percent of lane area Anchor: #WIHUOBUH

- FAL - failures, number Anchor: #PVGAISCJ

- BLK - block cracking, percent of lane area Anchor: #SSNRSDQG

- ALG - Alligator Cracking, percent of wheel path length Anchor: #EPVWDXXU

- LNG - Longitudinal Cracking, Average feet of cracking in each 100 ft of surface Anchor: #MVQVHNEX

- TRAN - Transverse Cracking, Number of transverse Cracks per station� Anchor: #PDOWCPNK

- RAV - Raveling, percent of rated lane’s total surface area. Anchor: #MVPCGWKN

- FL - Flushing, percent of the rated lane’s wheel path length