Section 2: External Factors that Influence Marking Performance

Anchor: #i1020445Introduction

Many factors influence the performance of a given pavement marking material. The major factors can be grouped into three categories:

- roadway surface

- traffic

- environmental.

Each category plays a factor in the performance of nearly every pavement marking material. Therefore, each of the categories should play a role in the material selection process. For any material, it is absolutely necessary that the pavement surface be clean and dry prior to marking placement to achieve proper pavement marking performance.

Anchor: #i1020483Roadway Surface Characteristics

The roadway surface that a given material is placed upon is one of the most important factors influencing pavement marking performance. In Texas, pavement markings are placed upon three general types of roadway surfaces:

- hot-mix asphalt concrete (HMAC)

- hydraulic cement concrete (HCC, also known as Portland cement concrete)

- open-graded bituminous pavements (referred to as surface treatments in this handbook, but also known as seal coats).

Engineers can expect a given pavement marking material to perform differently on each of the different surface types. Three major pavement surface characteristics that affect marking performance are:

- surface roughness

- heat sensitivity

- surface porosity.

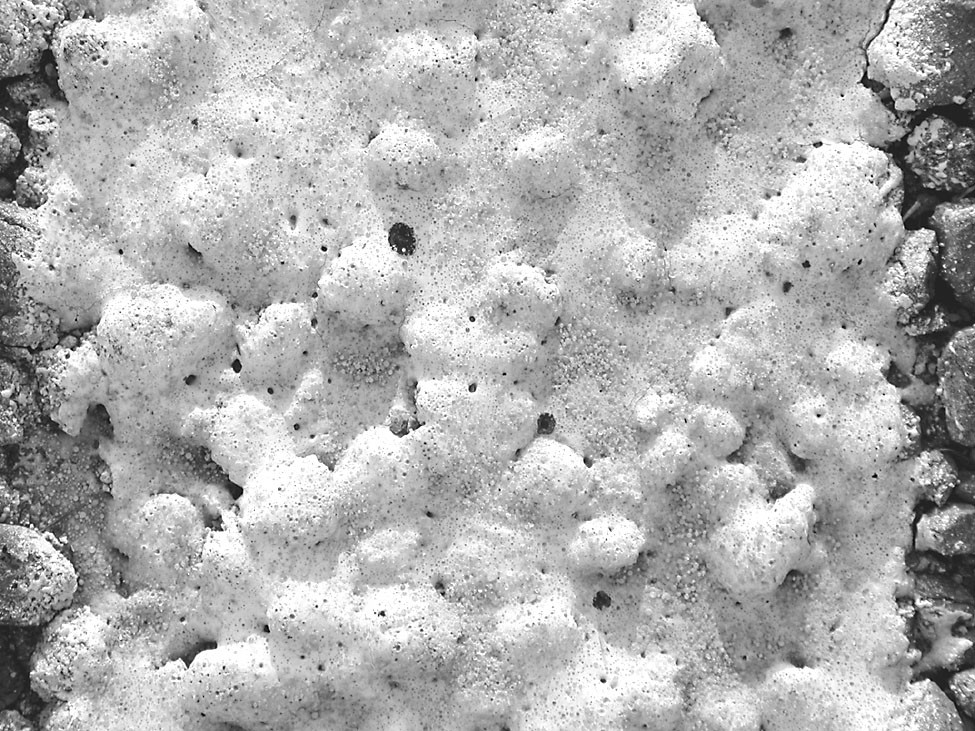

Surface Roughness. Surface roughness can play a major role in the way a marking performs over time. Pavement markings on rough pavement surfaces, such as surface treatments, commonly lower retroreflectivity and shorten service lives when compared to identical markings on smooth pavement surfaces. Figure 2-1 shows a typical thermoplastic marking on a new surface treatment. Table 2-1 lists some of the negative effects that rough pavement surfaces have on standard pavement markings. Applying a thicker pavement marking or allowing sufficient time for traffic to compact the pavement surface are the usual countermeasures to the problems associated with rough surface treatments, especially for thermoplastic materials.

Figure 2-1. Typical 100-mil thermoplastic marking on new grade-3 surface treatment.

|

Problem |

Cause |

|---|---|

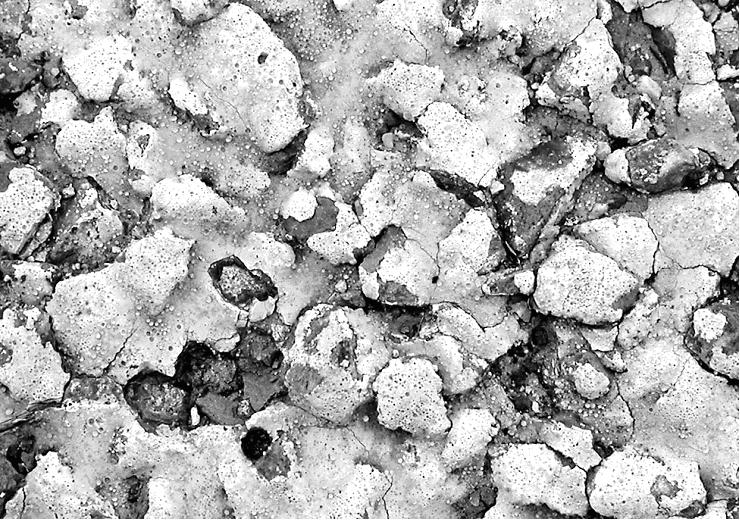

|

Lower overall retroreflectivity |

Because of irregular pavement surface characteristics, a high percentage of the binder and beads fall into the surface voids and crevices, greatly reducing the retroreflectivity of the marking ( Figure 2-2). |

|

Low material durability on top of aggregates |

Exposed binder material on top of aggregate results in material wearing off quickly ( Figure 2-3). |

|

Poor retroreflectivity on backside of aggregate |

Momentum of the striping truck causes the front sides of the aggregates to receive ample binder and bead coverage, while the backsides remain uncoated ( Figure 2-4). |

|

Bead loss on top of aggregates |

Thin binder material on top of the aggregates results in poor bead embedment and adhesion ( Figure 2-5). |

Figure 2-2. Beads falling between aggregates.

Figure 2-3. Poor material durability on top of aggregates.

Figure 2-4. Poor material coverage on backside of aggregate.

Figure 2-5. Poor bead retention on top of aggregates.

Heat Sensitivity. The heat sensitivity of a pavement surface determines the bonding characteristics between the surface and most hot-applied marking materials. At temperatures greater than 160°F, asphalt behaves as a viscous liquid, which allows for thermal bonding with many hot-applied pavement marking materials. For example, thermoplastic materials bond to asphalt surfaces by melting and fusing with the asphalt. Thermal bonding provides for a tight bond between the surface and the marking. Concrete pavements do not react to hot-applied pavement markings in this way, and as such thermal bonding does not occur. In these cases, other bonding mechanisms are relied upon, which are often inferior to thermal bonding. It is for this reason that some hot-applied marking materials, such as thermoplastic, are not recommended for use on concrete surfaces.

Prior to being fully cured, asphalt-based surface treatments are especially susceptible to bleeding under high temperatures. When asphalt bleeding occurs, the asphalt material is often tracked onto the pavement markings, causing permanent discoloration. In addition, thermoplastics are applied at such high temperatures that they sometimes boil the asphalt to the surface of the marking. Table 2-2 lists some of the negative effects that asphalt bleeding may have on standard pavement markings.

|

Problem |

Cause |

|---|---|

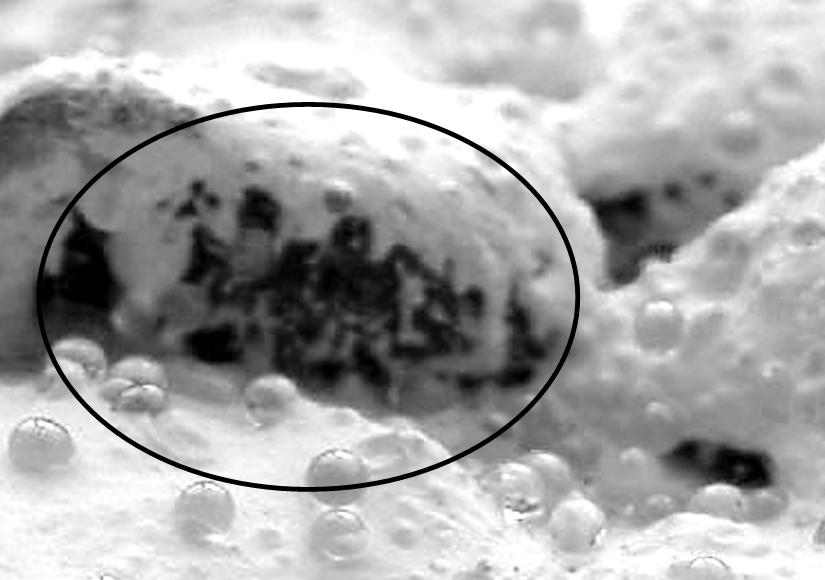

|

Spots of asphalt on markings |

On surface treatments with emulsified asphalt, the extreme heat of sprayed hot thermoplastic may boil the emulsion to the surface of the marking ( Figure 2-6). |

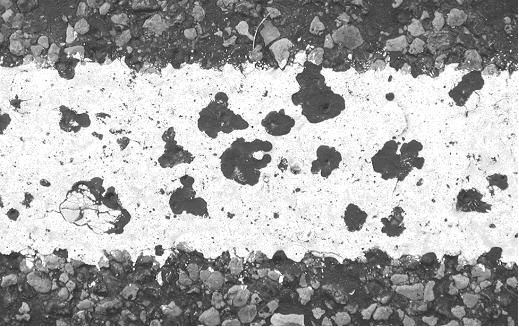

|

Markings covered with asphalt |

Insufficiently cured asphalt bleeds to the pavement surface and is tracked onto markings ( Figure 2-7). |

Surface Porosity. The surface porosity of a pavement surface determines the mechanical bonding characteristics for pavement markings with the surface. Mechanical bonding occurs when the pavement marking material seeps into the pores of the pavement surface and creates a tight mechanical bond upon drying. Thermoplastics and other hot-applied pavement markings adhere to concrete through mechanical bonding.

Figure 2-6. Asphalt boiling through hot thermoplastic.

Figure 2-7. Asphalt tracked onto markings.

Anchor: #i1020633Traffic

Traffic volumes greatly influence the performance of a pavement marking regardless of the pavement surface. The service lives of nearly all pavement marking materials are decreased when exposed to higher traffic volumes. However, some materials are clearly more resistant to traffic than others. Some agencies base pavement marking material selection primarily on traffic volume levels. Standard water-based paint often provides suitable performance on low volume roadways, thereby making it cost-effective. Durable pavement markings, such as thermoplastics, preformed tapes, and epoxies are often recommended for use on roadways with medium to high traffic volumes because paints often deteriorate rapidly under high-traffic conditions, and frequent restriping is not desirable. Under extremely high-traffic conditions or other locations where a high number of wheel hits on the markings are likely to occur, such as weaving areas or transverse markings, materials of the utmost durability are desirable.

Anchor: #i1020643Environmental

Environmental conditions can have a major influence on the performance of a pavement marking material. The effect of environmental conditions on performance can be broken in two separate categories:

- weather conditions when the marking is placed

- year-round climate.

The weather conditions when the marking is placed are often said to be one of the most influential factors in the performance of the marking. This is especially true for environmentally sensitive materials such as thermoplastics and tapes. Factors that should be considered include:

- temperature (air and pavement)

- humidity

- wind velocity

- surface moisture at the time of application.

Each of the above factors may affect marking performance. Air and pavement temperatures are important because most pavement marking materials require a minimum temperature for proper drying or curing. Humidity also affects the drying and curing times. Wind velocity affects drying times, but more importantly it affects the drop-on bead dispersion. Strong winds can prevent a high percentage of the drop-on beads from uniformly reaching the binder material. Pavement surface moisture at the time of application can have a severe effect on the bonding capabilities of the marking material to the pavement surface. Most materials require that the pavement surface be devoid of surface moisture prior to application to achieve bonding (see TxDOT Specification Item 666 4.2).

Year-round climatic conditions can also affect the long-term performance of a pavement marking material. Regions that receive heavy snowfall are often exposed to heavy abrasion on their pavement markings due to snowplow, sanding, and chemical activity. States in sun-belt regions may experience color fading and cracking of certain pavement marking materials due to intense ultraviolet exposure.