Section 3: Pavement Surface Preparation

Anchor: #i1020706Introduction

For all pavement marking materials, the pavement surface must be clean and dry to achieve proper bonding. Proper pavement surface preparation is absolutely critical to achieve good thermoplastic performance. A properly cleaned and dried surface is absolutely critical for maximum durability performance of nearly all markings — especially thermoplastic. A broom truck is often used to clean the pavement surface prior to striping as shown in Figure 2-8.

Figure 2-8. Typical brooming operation for surface cleaning prior to striping.

Special pavement heating devices are now available that are effective for removing pavement surface moisture and elevating the pavement surface temperature. These devices are especially effective on concrete surfaces.

Surface preparation must be performed in accordance with TxDOT Specification Item 678. If restriping over old markings, follow Table 2-3. Material Compatibility Matrix or manufacturer recommendations for material compatibility. Most materials can be used as restripe over materials of the same type, except preformed tapes and ceramic buttons, which should always be removed prior to restriping.

Anchor: #i1020745Compatibility of Materials for Restripe Situations

All pavement marking materials will at some point reach the end of their useful life. On many occasions, rather than obliterating the existing stripe, it is more cost-effective and convenient to simply restripe over the old markings without removing them, assuming that the old markings still adhere well to the roadway. However, for restriping to be effective, the material that is to be applied must be compatible with the existing pavement marking material. Table 2-3 shows a matrix of material compatibilities.

|

Existing |

Restripe (New) Material |

|||||||

|---|---|---|---|---|---|---|---|---|

|

(Old) Material |

Thermo |

WB Paint |

Tape |

Epoxy |

Polyurea |

Mod. Ureth. |

MMA |

Buttons |

|

Thermo |

Y |

Y |

N |

N |

N |

N |

N |

Y |

|

WB Paint |

Y |

Y |

N |

N |

N |

N |

N |

Y |

|

Tape |

N |

N |

N |

N |

N |

N |

N |

N |

|

Epoxy |

Y |

Y |

N |

Y |

– |

– |

– |

Y |

|

Polyurea |

Y |

Y |

N |

– |

Y |

– |

– |

Y |

|

Mod. Ureth. |

Y |

Y |

N |

– |

– |

Y |

– |

Y |

|

MMA |

Y |

Y |

N |

– |

– |

– |

Y |

Y |

|

Buttons |

N |

N |

N |

N |

N |

N |

N |

N |

Anchor: #i1020754

Marking Removal Methods

Existing markings should be removed if they are: too thick, losing adhesion to the pavement surface, of an incompatible material (Table 2-3), or if the marking layout must be reconfigured. Removal should be performed in accordance with TxDOT Specification Item 677. Approved methods include:

- flailing

- waterblasting

- sandblasting.

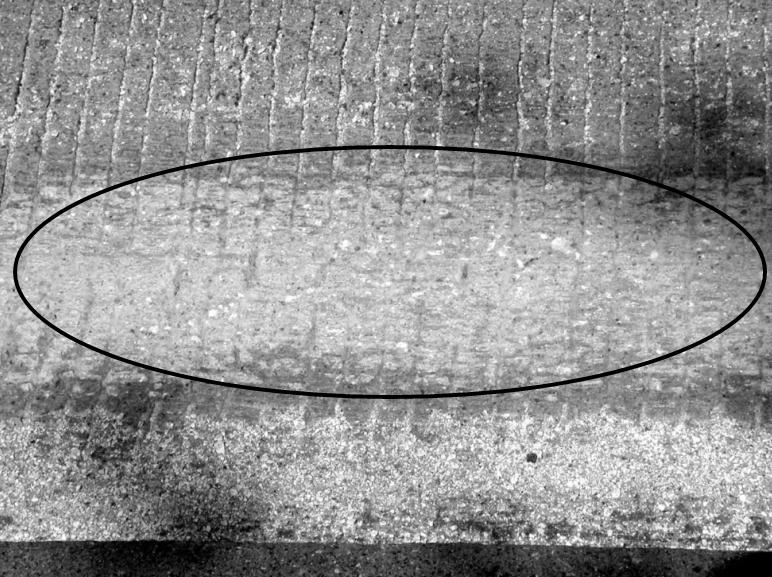

“Painting out” markings by covering over old pavement markings with black paint is not an acceptable removal technique. Note that the previous list of removal methods does not apply to buttons or tape. Figure 2-9 shows a properly removed marking using the flailing technique (prior to final brooming).

Figure 2-9. Properly removed marking using flailing technique.

Anchor: #i1020796Primer-Sealers

TxDOT Specification Item 666 requires the application of an acrylic or water-based paint primer prior to the application of most thermoplastic materials on concrete surfaces and oxidized asphalt surfaces where no marking exists. However, most transportation agencies favor the use of an epoxy primer in these situations. Primer is used on concrete surfaces because it penetrates into the concrete surface better than thermoplastic; thus the adhesion strength should be stronger. It does not act as a moisture barrier or eliminate the need for a dry surface at the time of pavement marking application. Primer-sealers are not required for restripe situations, as the existing marking will serve as the sealer. Note that restripe marking materials must be compatible with the existing marking material. Refer to Table 2-3. Material Compatibility Matrix or manufacturer recommendations for material compatibility.

Refer to TxDOT Specification Item 666 and manufacturer recommendations for specific information on the use of primer-sealers. Refer to Section 4 of this chapter or to manufacturer information for a detailed description of recommended application procedures for various pavement marking materials. If an uncommon or experimental pavement marking material is to be used, refer to specific manufacturer instructions for surface preparation and application of this material.