Section 3: Microfilm Requirements

Anchor: #i1017765Storage Environment

Storage of original microfilm must be stored in a separate building from that which duplicate copies, if any, or the original records are housed. All original microfilm must be handled microfilmed records with a retention period exceeding ten years must be stored in a temperature that does not exceed 70 degrees Fahrenheit, and a constant relative humidity of 35% must be maintained with a maximum variance of +/- 5.0% relative humidity in a 24-hour period.

- Anchor: #LIHNOFUP

- For microfilm of records with a retention of 10 years or more, temperature must not exceed 70 degrees Fahrenheit, and a constant relative humidity of 35% must be maintained with a maximum variance of plus/minus 5.0% relative humidity in a 24-hour period. Anchor: #SQDKMUYW

- For microfilm of records with a retention of less than 10 years, the maximum temperature must not exceed 77 degrees Fahrenheit, and a relative humidity range between 20% and 50% must be maintained with a maximum variation of plus/minus 5.0% relative humidity in a 24-hour period.

A typical air-conditioned office environment with stable temperature and humidity where microfilm will have minimum exposure to light and contaminants, is generally adequate for film to be retained for ten years or less.

Anchor: #i1017799Storage Facility Requirements for Original Microfilm Media

Original microfilm must be stored in a separate building from that in which duplicate copies, if any, or the original records are housed, and under conditions that meet the requirements of this section. Microfilm must be stored in a storage room or vault that complies with the following:

- Anchor: #EDTMPEAC

- Films of different generic types, such as silver-gelatin, diazo, and vesicular films, must not be stored in the same storage room/vault or in rooms sharing common ventilation. Anchor: #OETBNDXE

- Pack microfilm tightly to prevent oxidation. Anchor: #BYDRFQPX

- Store your records in a dark place and limit exposure to light. Anchor: #IFDBMTYK

- Is stored separate from other types of storage, offices, or work areas and offers protection from fire, water, steam, structural collapse, unauthorized access, and other potential hazards. Anchor: #FWOICEPK

- Is equipped with a fire alarm system and capable of preventing temperatures inside the storage room/vault from exceeding 150 degrees Fahrenheit and the relative humidity inside the storage room/vault from exceeding 85% for up to two hours in the event of a fire external to the storage room/vault. Anchor: #VCTWLXEI

- If constructed or readapted after 1991 to serve as a microfilm storage facility, is equipped with a fire suppression system and with automatic fire control dampers in ducts carrying air to and from the storage room/vault. Anchor: #GBQJGWEC

- If needed, is equipped with a system capable of removing those gaseous impurities in the surrounding environment as specified in standard ANSI IT9.11. Anchor: #BFTNEKCK

- If subject to invasion of solid particles that can abrade film or react on the images, has mechanical filters or electrostatic precipitators installed with a cleaning efficiency of at least 80% when tested with atmospheric air in accordance with standard ANSI IT9.11. Anchor: #CYKYRFSP

- Has approximately 0.05 inch of pressure above atmospheric pressure, e.g., a positive air pressure is maintained within the storage room or vault. Anchor: #DWJBXXBM

- Has adequate temperature and humidity controls. Anchor: #NWCAADFS

- Keep your storage facility clean. Anchor: #FGGOPVCO

- Don’t paint rooms without removing your microfilm first. Allow three months for paint to dry before replacing film in storage. Anchor: #PNOKNNUN

- Handle your microfilm carefully and use gloves as much as is logical to reduce oil residue transferring from your hands to the film. Anchor: #VODEWQEL

- Place acid-detection strips (A-D strips) next to your microfilm to catch increases in acetic acid as soon as possible. Anchor: #AYSCUJNH

- If film shows signs of degradation, determine which form of decay is happening and separate and quarantine film that is affected. This will help mitigate the possibility of other records contracting the issue.

Standards for Microfilm Containers

A microfilm container must be used for processed microfilm to protect the film and facilitate identification and handling. Chemically stable materials such as non-corrodible metals (anodized aluminum or stainless steel), peroxide-free plastics, and acid-free paper must be used for containers to ensure no degradation is caused to the image. If an adhesive is used, it must have no harmful effect on the photographic images. When transporting Microfilm Records 16mm and 35mm) to the Records Warehouse, make sure they are packed in individual acid-free containers.

Inks used on the container and on the label, must not be a source of products that may damage the film or the enclosure itself. Paper that is free of chemicals harmful to the film may be used to secure roll film, if needed. Microfilm must be stored in a closed housing or may be stored on open shelves or racks if the film is in closed containers.

Anchor: #i1017913Inspection of Stored Original Microfilm.

Microfilmed records must be retained and maintained in compliance with “Microfilming Standards and Procedures – Bulletin 2” established by Texas State Library and Archives Commission and TxDOT Districts and Divisions An inspection of stored microfilm must be conducted every two years, except if the microfilm has been stored under temperature and/or humidity conditions other than those specified in these sections, it must be inspected yearly.

When inspection is done, the sample of microfilm to be inspected for each storage room or vault, if more than one, must be 1/1000th of the total volume of stored microfilm or at least 100 microforms (rolls, jackets, microfiche, aperture cards, COM, etc.) whichever is greater. Sampling procedures must be established that will assure that all parts of the group of microfilm are represented.

If deterioration is found, a more extensive inspection must be conducted to locate all deteriorating film. Any deteriorating film must immediately be removed from the storage area and the problem corrected before returning the film to storage.

Anchor: #i1017938Vinegar Syndrome

Vinegar syndrome is a chemical of degradation that occurs with cellulous acetate film and is characterized by an obvious vinegar smell. Vinegar syndrome is a slow form of chemical deterioration that causes film to shrink, buckle, and emit a strong vinegar odor. This applies to media (microfilm) made with acetate backing; most film of this type was made prior to 1980. The degradation process releases acetic acid, the same substance in vinegar that gives it its smell which is the identifying characteristic of the degradation process.

There are three basic strategies for dealing with vinegar syndrome:

- Anchor: #QYAQWECA

- Improve storage conditions by reducing moisture and lowering the temperature. Anchor: #QBLCMBBY

- Quarantine any films identified as having vinegar syndrome to prevent the spread. Anchor: #RCPGSKIO

- Duplicate the film or convert it to a digital media.

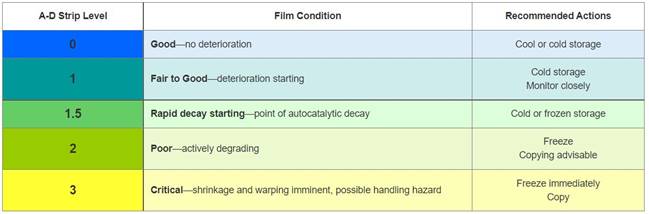

A-D Strip Testing

A-D Strips provide a simple and safe method for detecting, measuring, and recording the severity of "vinegar syndrome" in your acetate photographic film collections. A-D Strips are dye-coated paper strips designed to detect and measure the severity of acetate photographic film deterioration ("vinegar syndrome") in film collections. These acid-base indicator papers change color in the presence of acidic vapor given off by degrading film, providing an objective method to document the extent of vinegar syndrome and to determine when microfilm should be duplicated.

Figure 14-5. A-D Strips Level, Condition and Actions.

Anchor: #i1018010Microfilm Equipment

Districts and Divisions using microfilmed records need a means of reading the microfilm. The two basic types of microfilm equipment are:

- Anchor: #WSXDGMVN

- Readers. Readers are only for viewing microfilm, microfiche, or other microforms. The least expensive readers are for microfiche. More expensive readers have interchangeable carriages for viewing different microforms. Readers may have various other features, including motorized carriages for high-speed searching and retrieval, and/or digital displays for frame counters. Anchor: #BPEKIOEM

- Reader/printers. Reader/printers combine a reader with the capability to produce a paper copy of the image that is on the screen. They may be purchased with the same options described above.

Microfilm equipment, supplies are is available to purchase under PeopleSoft/Finance & Supply Chain module. Use the following Item IDs:

- Anchor: #DJIWVTUH

- Microfiche/Microfilm Readers/Printers: Item ID # 57576000000 Anchor: #NEWPXBSB

- Microfiche/Microfilm Readers: Item ID # 57572000000 Anchor: #GAXNDLSH

- Microfilm Accessories and Supplies: Item ID #s 57547000000, 57547140000, or 5747140000

Selecting Equipment

In addition to cost, consider these factors in selecting microfilm equipment:

Screen size – The reader screen should display an entire page of information at or near the original size of the record. The screen image will be the same size as the original record if the magnification of the lens on the reader equals the reduction ratio of the microfilm. (The reduction ratio is the amount a record is reduced on film. For example, a reduction ratio of 24:1 or 16:1 means a record is reduced to 1/24 of its original size.)

An 8½ by11-inch record filmed at a reduction ratio of 24:1 will be the same size as the original when viewed on a reader with a 24X lens.

A screen smaller than the original record will display a full page from the original if the magnification of the lens on the reader is less than the reduction ratio of the microfilm. An 8½ by 11-inch record filmed at a reduction ratio of 24:1 can be viewed in its entirety on a 7¼ by 9½-inch screen if the reader has 20X magnification. The entire image will be proportionately smaller than the original.

NOTE: A reader with a lens magnification greater than the reduction ratio of the microfilm will not display a full page from the original record unless the screen is proportionately larger.

Screen color - Neutral viewing screens are standard. They are available in tints of blue, green, and gray. Tinted screens reduce eyestrain, particularly in high-use situations.

Screen type - Most readers and reader/printers are the rear-projection type. They project the image from the rear of the unit onto the back of a translucent screen. Some of these screens are reversible. One side has a matte finish to reduce glare and reflections, and the other has a shiny surface for sharper images.

Unit size - The size of microfilm equipment varies. Small, portable readers fold into a traveling case. Desktop equipment is larger in size and most common. Larger freestanding units have many features, functions, and controls. Prices vary according to size and features.

Optics - Readers and reader/printers are specified by image magnification. For example, 24X means that the image is magnified 24 times. Lower-priced equipment has a fixed magnification. When selecting equipment for viewing different microforms, make sure the magnification of the equipment or lens is compatible with the reduction ratios of the microforms to be viewed. Equipment capable of handling a variety of microforms usually provides variable magnification through one of the following methods:

- Anchor: #BOYQMJYC

- Interchangeable lenses Anchor: #MQJAFTKM

- Dual lenses controlled by a lever or other mechanism Anchor: #PLRLNVGU

- Zoom lenses Anchor: #SASORTIL

- Special features. A device called a blip-chip is helpful on readers that have a motorized carriage and are used in high-retrieval situations. Electronic frame counters, or blips, are inserted on roll film as it is shot. The blip-chip reads the blips and displays the frame numbers as the motorized carriage goes through the film. When the desired frame number is displayed, the user can stop the film. (Frame numbers are identified in the index at the beginning of the film.) Most mid-priced to high-priced equipment with motorized carriages comes with a digital dis- play already installed.

Maintenance of Equipment

The quality of a microfilmed image, or a paper copy produced from the image, depends on the cleanliness of the optical system and printing mechanism. Dust on screens, mirrors or lenses reduces light and clarity. Dust particles can damage film and impair readability.

Prolong the life of microfilm equipment as follows:

- Anchor: #CAJDHGSE

- Use a dust cover when the equipment is not in use. Anchor: #BUUDQJUP

- Clean screens and optical systems routinely, following the manufacturer's recommendations. Anchor: #TDIJNINM

- Take care in loading paper, chemicals, and toner into reader/printers. Anchor: #KFHPFVAC

- When a bulb begins to darken, replace it. Anchor: #EVMEUATY

- Never touch halogen bulbs. They burn extremely hot and can ignite any residue of oil from human skin. Anchor: #TEHJQELI

- Inspect and clean equipment routinely. A small, handheld vacuum cleaner with a long, thin nozzle works well.

Integrating Microfilm and Emerging Technologies

With the proper equipment, microfilm images may be scanned to digital images. Large back-file conversions of microfilmed records to digital images are generally not practical unless the records are subject to a high rate of retrieval and reproduction or the scanning is necessary to arrest deteriorating images.

Large scale imaging projects are best handled by using a vendor who specializes in them. Microfilmed records converted to digital are subject to the requirements for electronic records described in Chapter 7, “Electronic Records”