Section 7: Bonded and Unbonded Concrete Overlays

Anchor: #i10154937.1 Introduction

Bonded concrete overlay (BCO) consists of a 2-in. to 8-in. thick concrete layer placed on top of the existing concrete pavement with operations conducted to ensure full bond between new and old concrete layers. A BCO with a minimum thickness of 4 in. is one of the most cost-effective ways of enhancing structural capacity of under-designed pavements by reducing deflections and extending service life. A BCO with a thickness of less than 4 in. is typically used to restore pavement surface characteristics, such as ride and friction.

The department maintains many miles of thin PCC pavement that have exceeded their design traffic projection and are still in reasonably good condition. The use of BCO is based on the fundamental design assumption that the old and new concrete layers behave as a monolithic layer. Providing full bond is of the utmost importance. During construction, specific steps are taken to enhance and ensure the full bond between old and new concrete as discussed in Chapter 10.

Bonded concrete overlays over jointed concrete pavements are difficult to construct because all joints must be matched. CRCP-bonded concrete overlays have been constructed and have performed successfully in several districts but have not been used widely throughout the state. Districts considering a bonded concrete overlay can contact MNT – Pavement Asset Management, Pavement Analysis & Design Branch, for assistance.

Unbonded concrete overlay consists of a concrete layer (5 in. or greater) on top of an existing concrete with a HMA interlayer to separate new overlay and existing concrete. An unbonded overlay is a feasible rehabilitation alternative for PCC pavement for practically all conditions. These types of rehabilitation methods are most cost-effective when the existing pavement is badly deteriorated because a reduced amount of repairs were made to the existing pavement prior to constructing the unbonded concrete overlay.

Unbonded CRCP concrete overlays may be used over CRCP, jointed concrete pavement (CPCD), or jointed reinforced concrete pavement (JRCP). Unbonded CRCP overlay uses the same design procedure as new CRCP pavements. This use of unbonded CRCP overlay can be credited for contributing to the structural capacity of the existing concrete pavement and results in a thinner concrete pavement design than required for CRCP constructed on a new location.

Anchor: #i10081217.2 AASHTO Overlay Thickness Design for Bonded Overlays

The equation below is used to calculate the overlay thickness to increase structural capacity to carry future traffic. The designer can also use the DARWin® 3.1 program and select the “Overlay Design” Module and “Bonded PCC Overlay of PCC Pavement.”

Dol = Df - Deff

Where:

Dol = required slab thickness of overlay, in.

Df = slab thickness to carry future traffic, in.

Deff = thickness of existing slab, in.

The slab thickness, Df, is determined for the design traffic as if it were built as a new pavement on the prepared base. Use the design procedure in Sections 3 or 4 for the pertinent pavement type. Some existing pavements might not have stabilized bases, and the k-value should be evaluated using FWD or DCP.

Determination of existing Effective Slab Thickness by Condition Survey Method

Deff = Fjc * Fdur * Ffat * D

Where:

Fjc = joints and cracks adjustment factor

Fdur = durability adjustment factor

Ffat = fatigue adjustment factor

D = thickness of existing slab, in.

For BCO design, the condition of the existing pavement is one of the most important factors. If the pavement condition is deteriorated in the form of punchouts and deteriorated cracks, BCO may not be a good alternative.

The items that should be surveyed are:

- Anchor: #VELQHWSE

- the number of punchouts per mile, Anchor: #ALCCDMTR

- the number of deteriorated transverse cracks/joints per mile, Anchor: #VVEJFMEM

- the number of existing and new repairs prior to the overlay per mile, Anchor: #IIIJUCPM

- presence of D-cracking or ASR cracking, and Anchor: #WDIJCFVL

- evidence of pumping of fines or water.

Punchouts are the only structural distresses in CRCP; the number of punchouts per mile is a good indication of the structural condition of the existing pavement. If there are more than 12 punchouts per mile, then the pavement is in poor structural condition and may not be a good candidate for BCO.

The number of deteriorated transverse cracks per mile is the next item to be surveyed. Even though some transverse cracks may appear to be deteriorated, quite often they are structurally in good condition. In Texas, it is rare to observe deteriorated transverse cracks, except for spalled cracks. Most spalled cracks are not necessarily structurally deficient. Based on the research findings, it is recommended that only transverse cracks much wider than normal, along the entire length of the transverse crack and across the entire lane width, should be counted as “deteriorated transverse cracks.”

The number of patches per mile and evidence of pumping should be recorded. In Texas’ old concrete pavements, typically, the base was not stabilized and pumping resulted. Durability related problems, such as D-cracking and ASR cracking, should be noted and their severity recorded. Overall, it has been quite rare to observe durability-related problems in concrete pavement in Texas.

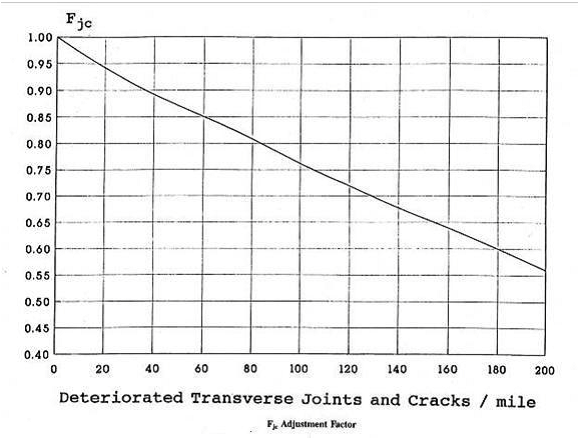

Anchor: #NSIUCTPS7.2.1 Joints and Cracks Adjustment Factor, Fjc

The Joints and Cracks Adjustment Factor, Fjc, accounts for the extra loss in the present serviceability index (PSI) caused by deteriorated reflection cracks in the overlay. Deteriorated reflection cracks develop due to unrepaired deteriorated joints, cracks, and other discontinuities in the existing slab prior to the overlay.

A deteriorated joint or slab will rapidly reflect through an overlay and contribute to loss of serviceability. Therefore, full-depth repair is recommended on all deteriorated cracks and any other major discontinuities in the existing pavement prior to overlay. The target Fjc is 1.00.

If it is not possible to repair all the deteriorated areas, use the total number of unrepaired deteriorated joints, cracks, punchouts, and other discontinuities per mile in the design lane to determine the Fjc from Figure 8-5.

Figure 8-5. Joints and Cracks Adjustment Factor for Bonded Overlays, Fjc. Source: AASHTO Guide for Design of Pavement Structures (1993)

Anchor: #XCLSRMGI7.2.2 Durability Adjustment Factor, Fdur

The Durability Adjustment Factor, Fdur, adjusts for an extra loss in PSI of the overlay when the existing slab has durability problems, such as D-cracking or reactive aggregate distress. Fdur is determined using historical records and condition survey data. Table 8-5 shows the durability adjustment factor.

|

Durability Adjustment Factor, Fdur |

Historical Records and Condition Survey Data |

|---|---|

|

1.00 |

No evidence or history of PCC durability problems. |

|

0.96 – 0.99 |

Pavement is known to have PCC durability problems, but there is no visible spalling. |

|

0.88 – 0.95 |

Cracking and spalling exist (in these conditions, a bonded PCC overlay is not recommended). |

Anchor: #QLGSCFPS

7.2.3 Fatigue Damage Adjustment Factor, Ffat

The Fatigue Damage Adjustment Factor, Ffat, adjusts for past fatigue damage in the slab. It is determined by observing the extent of punchouts (CRCP) that may be caused primarily by repeated loading. Table 8-6 shows the fatigue damage adjustment factor.

|

Fatigue Damage Adjustment Factor, Ffat |

Historical Records and Condition Survey Data |

|---|---|

|

0.97 – 1.00 |

Few transverse cracks/punchouts exist (none caused by D-cracking or reactive aggregate distress), < 4 punchouts per mile. |

|

0.94 – 0.96 |

A significant number of transverse cracks/punchouts exist (none caused by D-cracking or reactive aggregate distress), 4 to 12 punchouts per mile. |

|

0.90 – 0.93 |

A large number of transverse cracks/punchouts exist (none caused by D-cracking or reactive aggregate distress), > 12 punchouts per mile. BCO is not recommended. |

Anchor: #SHONAOPV

7.2.4 Reinforcement Design

Reinforcement should be placed at a depth that provides a minimum concrete cover of 3 in. When BCO thickness is 3 in. or less, reinforcement in the form of longitudinal steel is not recommended. For thinner overlays, fibers have been successfully used.

The design engineer will determine the reinforcement bar size and number of longitudinal steel, tie bars, and transverse steel. The performance of CRCP depends on the percentage of longitudinal steel. Failing to place longitudinal steel in a BCO 4 in. or thicker will effectively reduce the percentage of longitudinal steel in the combined slab, which could increase steel stresses and make transverse crack widths larger. See the recommended reinforcing steel percentage and vertical location in Table 8-7.

|

BCO Thickness |

Longitudinal Steel (%) |

Vertical Location |

Fibers |

|---|---|---|---|

|

≤ 3 in. |

N/A |

N/A |

Yes |

|

≤ 5 in. |

0.6% |

Bottom of BCO |

No |

|

> 5 in. |

0.6% |

Middle of BCO |

No |

Anchor: #i1008365

7.3 AASHTO Overlay Thickness Design for Unbonded Concrete Overlays

The 1993 AASHTO Guide for Design of Pavement Structures is recommended for unbonded concrete overlay thickness design. The designer can use the AASHTO DARWin® 3.1 program and select the “Overlay Design” Module and “Unbonded PCC Overlay of PCC Pavement.”

7.3.1 Overlay Thickness Design

Dol = (Df2 - Deff2)1/2

Where:

Dol - required slab thickness of overlay, in.

Df = slab thickness to carry future traffic, in.

Deff = effective thickness of existing slab, in.

Determination of Effective Slab Thickness by Condition Survey Method

Deff = Fjcu * D

Where:

D = existing slab thickness, in. (Use 10 in. when existing D > 10 in.)

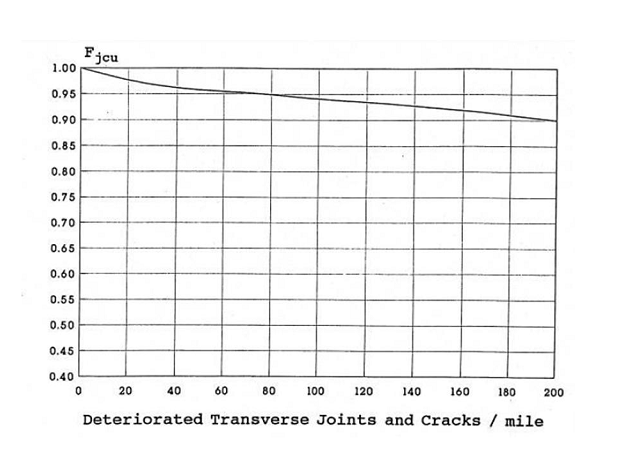

Fjcu = joints and cracks adjustment factor

Fjcu adjusts for PSI loss due to unrepaired joints, cracks, and existing expansion joints, exceptionally wide joints (> 1 in.), or AC full-depth patches.

Use the total number of unrepaired deteriorated joints, cracks, punchouts, and other discontinuities per mile in the design lane to determine the Fjcu from Figure 8-6.

Figure 8-6. Joints and Cracks Adjustment Factor for Unbonded Overlays, Fjcu Source: AASHTO Guide for Design of Pavement Structures (1993)

7.3.2 Reinforcing Steel Design

The reinforcing steel placements are the same as new CRCP when unbonded overlay is 7 in. or thicker. When unbonded overlay is less than 7 in., use longitudinal reinforcement at about 0.6% of concrete cross-sectional area. The design engineer will determine the steel bar size and quantities for longitudinal bars, tie bars, and transverse bars, and consult with the Pavement Analysis & Design Branch of MNT – Pavement Asset Management.

More information about bonded and unbonded concrete overlays is detailed in “Bonded Concrete Overlay” and “Unbonded Concrete Overlay” in Chapter 10, “Rigid Pavement Rehabilitation.”