Section 8: Information Needed for Pavement Design

Anchor: #i10089908.1 Introduction

Specific and accurate information is needed and critical for effective decisions regarding pavement design and rehabilitation. The information will also be included in the pavement design report. This section discusses the major requirements critical to a pavement design:

- Anchor: #HVENESMM

- traffic loads Anchor: #NYDLWYJY

- serviceability index Anchor: #ALBSHSLS

- reliability (confidence level) Anchor: #NIVGUBVT

- material characterization Anchor: #JJQRDHID

- drainage characteristics Anchor: #UFTAUQEY

- existing functional and structural condition evaluation.

8.2 Traffic Loads

One of the primary functions of a pavement is load distribution. Therefore, in order to adequately design a pavement, representative loading characteristics must be presumed about the expected traffic it will encounter. Loads, the vehicle forces exerted on the pavement (e.g., by trucks, heavy machinery, airplanes), can be characterized by the following parameters:

- Anchor: #QTRMDTOP

- individual tire loads Anchor: #EQDNSMXQ

- axle and tire configurations Anchor: #EUIXEOWR

- typical axle load limits Anchor: #FLHOIRFB

- repetitions of axle loads Anchor: #QTOQTHEL

- traffic distribution (by direction and lane) Anchor: #QSKDAFKU

- traffic projections (current volume and growth rate).

Traffic loads, along with environment, damage pavement over time. The simplest pavement structural model asserts that each individual load inflicts a certain amount of unrecoverable damage. This damage is cumulative over the life of the pavement, and when it reaches some maximum value, the pavement is considered to have reached the end of its useful service life.

8.2.1 Tire Loads

Tire loads are the fundamental loads at the actual tire-pavement interface and are generally assumed to be equal for all tires on any given axle. For most pavement analyses, it is assumed that the tire load is uniformly applied over a circular area. Also, it is generally assumed that tire inflation and contact pressures are the same.

8.2.2 Axle and Tire Configurations

While the tire contact pressure and area is of vital concern in pavement performance, the number of contact points per vehicle and their spacing is also critical. As tire loads get closer together, their influence areas on the pavement begin to overlap, especially at depth. At this point, the design characteristic of concern is no longer the single isolated tire load, but the combined effect of all the interacting tire loads. Therefore, axle and tire arrangements are quite important.

Tire-axle combinations (see Figure 2-11) are typically described as:

- Anchor: #GDONOONJ

- single axle – single tire (truck steering axles, etc.) Anchor: #JSQRBQAC

- single axle – dual tires Anchor: #EHYGDPQT

- tandem axle – single tires Anchor: #CRMDJRHS

- tandem axle - dual tires.

Figure 2-11. Tire axle configurations.

Other axle configurations exist (tridem [or three axle], quad [or four axle]), but generally represent a small fraction of the entire population.

8.2.3 Typical Axle Load Limits

Federal and state laws establish maximum axle and gross vehicle weights to limit pavement damage. The range of weight limits in the U.S. varies, based on federal and state laws.

|

Axle** |

Limits (lb.) |

|---|---|

|

Single Axle |

20,000 |

|

Tandem Axle |

34,000 |

|

Gross Vehicle Weight |

80,000 |

|

*Based on various federal and state laws. **Limits for tridem and quad axles are generally governed by the bridge formula:

Where:

|

|

8.2.4 Repetitions of Axle Loads

Wheel and axle loads for an individual vehicle are not difficult to determine. However, the number and types of wheel/axle loads a particular pavement will be subject to over its entire design life become complicated to determine and are subject to uncertainties in traffic growth and changes to the traffic stream composition over time. Ultimately, it is not the wheel load, but the damage to the pavement caused by each wheel load that is of primary concern.

There are two basic methods for characterizing axle load repetitions:

- Anchor: #ODWESMOO

- Equivalent single axle load (ESAL). Based on AASHO Road Test results, the most common approach is to convert axle configuration and axle loads of various magnitudes and repetitions (‘mixed traffic’) to an equivalent number of “standard” or “equivalent” loads. The most commonly used equivalent load in the U.S. is 18,000 1b. equivalent single axle load (normally designated ESAL). This is the loading format used in FPS 21, DARWin® 3.1, and TxCRCP-ME. Anchor: #VTWSLLXH

- Load spectra. AASHTOWare Pavement ME (AASHTOWare mechanistic-empirical design system) essentially does away with the ESAL statistic and determines loading effects directly from axle configurations and loads. This is a more precise characterization of traffic but relies on the same raw input data used to calculate ESALs.

A typical load spectrum input would be in a form of a table that shows the relative axle load frequencies for each common axle combination (e.g., single axle, tandem axle, tridem axle, quad axle) over a given time period. A separate table with the breakout of trucks by class (classes 4-13) tied to an initial average annual daily truck traffic (AADTT) count and growth rate are also needed. Load spectra data are commonly obtained from weigh-in-motion stations.

8.2.5 Traffic Distribution

Along with load type and repetitions, the load distributions across a particular pavement geometric section must be estimated. For instance, on a six-lane interstate highway (3 lanes in each direction) the total number of loads is probably not distributed exactly equally in both directions. Often, one direction carries more loads than the other. Within that one direction, not all lanes carry the same loading. Typically, the outermost carries the most trucks and is subjected to the heaviest loading.

As a result, pavement structural design should account for these types of unequal load distribution. This is usually accounted for by selecting a “design lane” for a particular pavement. The loads expected in the design lane are either a) directly counted or b) calculated from the cumulative two-direction loads by applying factors for directional distribution and lane distribution.

The 1993 AASHTO Guide offers the following basic equation:

Where:

- Anchor: #XGJRDAUH

- w18 = traffic (or loads) in the design lane. Anchor: #FYWAAGKQ

- DD = directional

distribution factor, expressed as a ratio, that accounts for the

distribution of loads by direction (i.e., east-west, north-south).

- Anchor: #KXAHESJR

- Example: One direction may carry a majority of the heavy truck loads; that direction would be designed differently or, at a minimum, control the structural design. Generally taken as 0.5 (50%) for most roadways unless more detailed information is known.

Anchor: #WVTJAXUP - DL = lane distribution factor, expressed as a ratio, accounts for the distribution of loads when two or more lanes are available in one direction. Anchor: #MWHTNWLU

= the

cumulative two-directional 18-kp ESAL units predicted for a specific

section of highway during the analysis period.

= the

cumulative two-directional 18-kp ESAL units predicted for a specific

section of highway during the analysis period.

For instance, on most interstate routes, the outside lane carries a majority of the heavy truck traffic and would be the design lane.

The Transportation Planning and Programming Division (TPP) posts a directional distribution statistic in the Traffic Analysis for Highway Design report, but this distribution is related to peak ADT distributions (the 30th highest hourly volume) that affect level of service for geometric design as opposed to loading for structural design.

The assumption made in the Traffic Analysis for Highway Design report is traffic loading is equivalent in both directions. If the designer anticipates the truck directional distribution to be different from 50/50 or loads to be significantly greater in one direction, then this concern should be indicated in the request (Form 2124) submitted to TPP for project level traffic data.

Recommended lane distribution factors for both flexible and rigid pavements designs are:

|

Traffic Lanes in One Direction |

Lane Distribution Factor |

|---|---|

|

1 or 2 |

1.00 |

|

3 |

0.70 |

|

4 or more |

0.60 |

8.2.6 Traffic Projections

TPP provides traffic projections (“Single Source Traffic Data Operating Procedures” from the Transportation Planning Policy Manual, Chapter 3, Section 4). The designer must request a 20-yr. traffic projection for flexible pavements and a 30-yr. traffic projection for rigid pavements from the Traffic Section of TPP.

For pavement design purposes, external and internal requests for traffic projections should be coordinated with the district director of Transportation Planning and Development (TPD). The district will use Form 2124, Request for Traffic Data.2 External requests for traffic data for purposes other than pavement design must be immediately referred to the open records coordinator assigned to the district, division, or office that received the request.

CAUTION: Close coordination is needed with the district TPD to ensure timely turnaround of traffic data for pavement structural design. For quick turnaround, check ONLY box “1” on Form 2124. For check box “1” data, time frame to receive data should be no more than 7-10 business days.

If the district has need of other data options on the form (environmental studies, line diagrams, or corridor analyses), the district submitter should make clear on Form 2124 that box “1” requirements should be given priority. The data for check box “1” will be sent to the district in the quick turnaround time frame with the other requirements sent at a later date.

Units of Measurement. Currently, traffic loading is only rendered in terms of ESALs (versus axle load spectra). This is the standard method of evaluating loads for highways designed by the department. ESALs are evaluated for flexible and rigid pavements differently as a result of empirical relationships developed following the AASHO Road Test. Estimates for each type of pavement will be different. ESAL estimates will also vary slightly based on the overall pavement structure (also a result of empirical relationships).

Loading Estimates. The default structure used by the Traffic Section of TPP for traffic loading estimates is an 8 in. rigid slab or a flexible pavement of structural number (SN) 3. The SN is a structural thickness index used in the AASHTO 93 method of flexible pavement design. These structural classes (8-in rigid slab or SN=3 for flexible) are for highways with light to moderate traffic, but ESALs generated for these structures result in more conservative structural thicknesses and are preferred for comparative design when considering alternate pavement types. An option for highways with moderate to heavy traffic is to provide TPP with the closest estimate for the appropriate structural class in terms of SN (flexible pavement) or thickness in inches (rigid slab).

Projections and Special Factors. The designer must ensure that all pertinent information regarding characteristics of the project that influence traffic loading are made known to traffic analysts in TPP. Use Form 2124, Request for Traffic Data1, to request traffic data. For structural pavement design, supply administrative data on Form 2124 including:

- Anchor: #IQKECBJG

- District, County, CSJ Anchor: #DUOOIAIG

- Highway designation (System and Number) Anchor: #OIJOIBJM

- Limits (beginning and ending geographical/offsets in decimal miles from highway intersection) Anchor: #JFAQMSPD

- Beginning and ending reference markers and offsets Anchor: #EOQGLGBC

- Y/N. Is the project in the Unified Transportation Plan (UTP)? The UTP is the 11-yr. statewide plan for transportation project development Anchor: #MQPWFGFJ

- District Priority, Estimated Letting Date Anchor: #KLBFCEQM

- Existing Number of Lanes (total) Anchor: #JPCNMLBR

- Proposed Number of Lanes (total) Anchor: #CHFBMJPS

- District Contact Person and Phone Number. Anchor: #HJCHTJEU

- Include a location map of the project,

noting any existing or proposed development that will be a traffic

generator. This is critical. Be as detailed as possible in identifying

traffic sources, include whether loading is anticipated to be heavier

in one direction (e.g., gravel haulers leaving a pit, etc.). Other

examples of special situations:

- Anchor: #DMUMUOTI

- a street that is or will be a major arterial route for city or school buses Anchor: #BCVMCQBT

- a roadway that will carry truck traffic to and from heavily used distribution or freight centers Anchor: #WDTLIAIO

- a highway that will experience an increase in traffic due to a connecting major high-traffic highway that will be constructed in the near future Anchor: #IXCBCQMP

- a roadway that will experience a decrease in traffic due to the future opening of a parallel/bypass roadway facility Anchor: #QWHKHTIO

- an increase in oil/gas field drilling or wind generator permits along a corridor.

Anchor: #DXQJGLAC - Check box “1” for “Basic Highway Traffic

Data” for pavement design that includes:

-

Anchor: #DPFNTWQA

- Base year/Beginning year (year project will be open to traffic following the proposed construction/rehabilitation) Anchor: #SSMXEAMW

- Desired forecast interval (20-yr., 30-yr., or both) Anchor: #UABSHCXD

- Rigid pavement slab thickness. NOTE: The default is 8.0 in. If the slab will be thicker than 8.0 in., consult with MNT – Pavement Asset Management before changing. Anchor: #QPCCISFN

- AASHTO structural number for flexible pavements. NOTE: The default is 3. If the pavement structure will result in a higher structural number, consult with MNT – Pavement Asset Management before changing

Not specifically included on this form is a field for identifying roadbeds. When multiple roadbeds exist along a corridor, identify the required roadbed by mainlanes or frontage roads and by direction, if necessary. Make clear which lanes traffic data are being requested for so the design will reflect traffic loading specifically for the intended project scope.

8.2.7 Adjusting TPP-Supplied Traffic Data

Districts should review the “Traffic Analysis for Highway Design” report to verify reasonableness. Trucks have the largest impact on ESALs and, therefore, the simplest screening check is to verify the percentage of truck traffic in the average daily traffic (ADT) through observation. A simple ratio of actual truck percentages versus those estimated by TPP can be applied to the TPP estimated ESALs as a quick update for design purposes. A 48-hour continuous classification count within the project limits should be considered for jobs where extreme traffic loading is anticipated. Assigning reasonable truck factors (ESALs/truck) and growth rates to project cumulative ESALs over the design period can be performed using the DARWin® 3.1 ESAL generator or similar tool to compare against TPP supplied traffic data.

There may be occasions where the traffic forecast data supplied by TPP becomes slightly dated due to project letting delays or the original data supplied is for the wrong analysis time interval (e.g., 30-yr. data needed, but only 20-yr. data requested). In these cases, the designer may use TRAFFIC6.xls or similar routine to interpolate or extrapolate ADT and cumulative ESAL data using the same formula embedded within FPS. This formula automatically adjusts 20-yr. traffic data to match the user-selected analysis period. Use with caution; for job locations where traffic patterns have recently changed or will change in the near future, major roadways, or other jobs where the original traffic forecasts are more than 5 years old, the designer is encouraged to request an updated forecast from TPP.

For more information on traffic projections, refer to Chapter 1, Section 4 “ 10430: Obtain traffic data” in the Project Development Process Manual.

Anchor: #i10094198.3 Serviceability Index

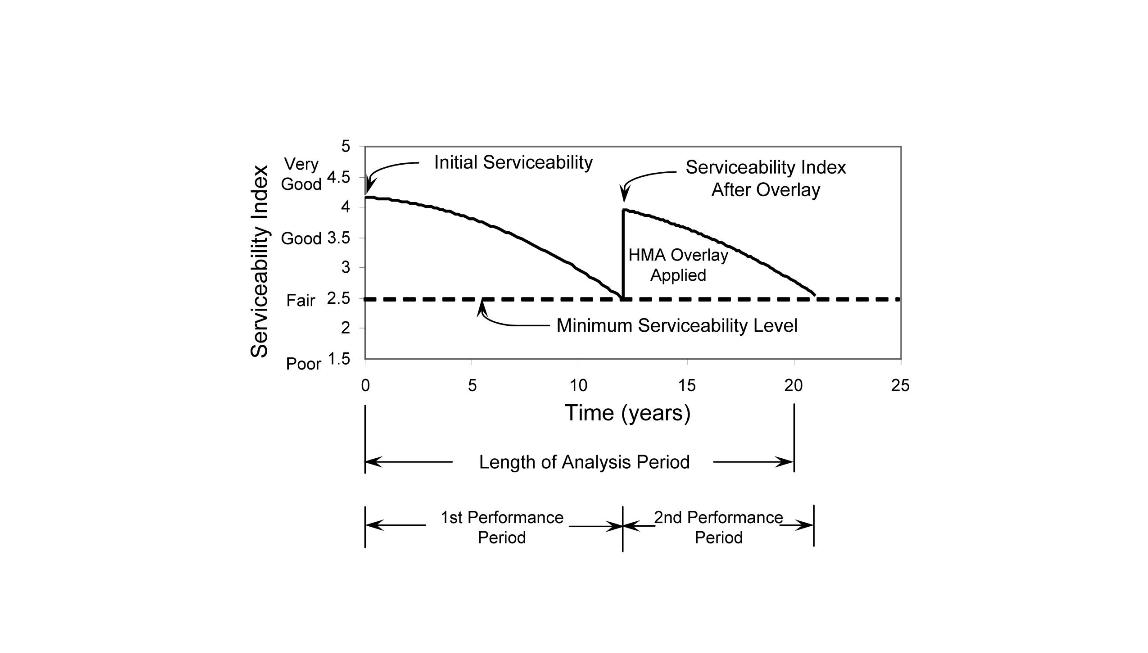

Serviceability is a concept derived during the AASHO Road Test. This concept is related to the primary function of a pavement structure: to provide the traveling public with a smooth, comfortable, and safe ride. A scale ranging from 0 to 5 is used to evaluate a pavement’s present serviceability index (PSI); pavement with a rating of zero is impassible and a rating of 5.0 would be perfectly smooth. Figure 2-12 illustrates the concept of serviceability index.

All pavements, when newly constructed or rehabilitated, are expected to begin at a high level of serviceability with a decrease in serviceability over time and traffic loading as the pavement becomes more distressed and rough.

Typically, the initial serviceability of a pavement will be about 4.0 or higher (5.0 is a lofty, but inaccessible goal, and levels below 2.0 are not considered acceptable). Pavement managers strive to keep the minimum “terminal” serviceability index at a level that will not be indicative of a public safety hazard or discomfort or be excessively costly in rehabilitative effort.

Smooth highways minimize dynamic axle loading; typically, the smoother a pavement begins its life, the longer the time to initiate rehabilitation. The change in serviceability over time is also known as “performance.” General pavement performance relationships are illustrated in 'Pavement Performance Relationships.'

Figure 2-12. Pavement Performance Relationships.

Anchor: #i10197038.4 Reliability (confidence level)

The concept of reliability as applied to pavement design can be defined as the probability that the pavement will perform as intended under the design traffic loading, and other crucial design inputs (material properties, environmental factors, etc.).

Reliability for pavements designed using the department’s recommended design programs is related to maintaining serviceability at or above the specified minimum (terminal) serviceability index throughout the desired performance period or design life. The department generally uses a reliability of 90 to 95% for rigid pavements and higher volume flexible pavements. Lower reliability, consistent with managed risks, may be appropriate for low to medium volume flexible pavements. For any given pavement structure, the serviceability at the end of this period is typically assumed to have a normal distribution with a mean and standard deviation.

The critical design inputs will have some variability associated with them; the assigned modulus values for the subgrade and other materials used in the structure, the construction process (in-place densities, layer thickness, etc.), traffic load predictions, and the design equation itself all have variability. Generally, the higher the reliability of a designed structure, the thicker the structure will be. Otherwise, the thickness must be offset using higher quality or stabilized materials. Since the assigned confidence level adjusts the calculations to account for material variability in the agglomeration of all inputs, including traffic, select an average modulus (based on specific material type, considering seasonal variation) for all inputs.

Anchor: #i10094728.5 Material Characterization

For structural design of pavements, an accurate characterization and determination of layer moduli is desired, particularly for flexible pavement design. Pavement layers can be characterized with laboratory testing or field testing.

Laboratory tests can be used to determine the parameters that affect properties of materials, such as moisture susceptibility, stress level, strain amplitude, and the strain rate. The moduli derived from these laboratory tests (triaxial loading, seismic):

- Anchor: #CFUKTVAP

- can be either smaller or larger than moduli determined from in situ testing and Anchor: #SKAOKRMG

- are not compatible with inputs required in FPS 21.

Field tests are more practical and preferred because they can be performed rapidly and may be used to test a large volume of material at multiple project locations in its natural state-of-stress. On the whole, it is more likely the project can be better characterized using field tests rather than relying on the evaluation of samples taken from a few discrete locations.

8.5.1 Laboratory Measurements of Moduli

The common way to develop the stress-strain relationship is through laboratory tests. The most recognized laboratory test method in pavement engineering, especially for flexible pavements, is the resilient modulus (Mr) test.

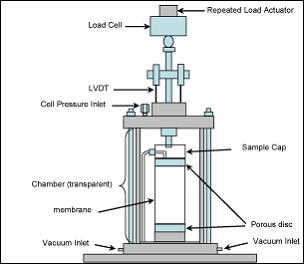

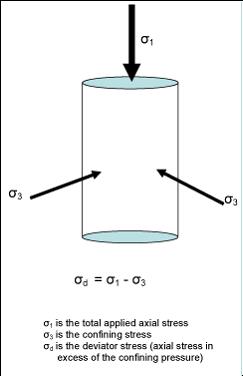

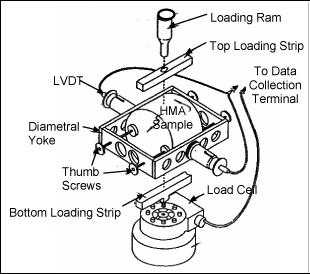

The testing procedure for the resilient modulus consists of subjecting a specimen to a sequence of confining pressure and cyclic deviatoric stress levels. The load pulse consists of a haversine load with a duration of 0.1 sec. loading followed by a rest period of 0.9 sec. Up to 1,000 load cycles may be applied. The load applied to the specimen is monitored by a load cell. The resilient deformation is measured with Linear Variable Differential Transducers (LVDT).

The resilient modulus is the ratio of the repeated axial deviator stress divided by the recovered axial strain. Research is also exploring seismic tools to evaluate modulus of laboratory-prepared samples.

8.5.2 Base and Subgrade Materials

The base and subgrade materials, depending on their gradation and plasticity, can be divided into two groups, fine-grained (cohesive) or coarse-grained (cohesionless or granular). The constitutive properties of both materials are defined based on the state of stress applied to them.

The recommended and simplified constitutive model can be expressed as:

Where:

Mr = resilient modulus

σc and σd = confining and deviatoric pressure, respectively

k1, k2, and k3 = coefficients determined from the results of laboratory tests

The model is universally applicable to fine-grained and coarse-grained base and subgrade materials. For unbound materials, AASHTO T 307 is currently used to determine resilient modulus. Sealed latex membranes are placed around the molded triaxial specimens and subsequently placed in a sealed pressure chamber. The specimen and chamber are placed under a loading mechanism in a load frame. Constant confining pressure is applied to the membrane as axial loading is applied in haversine-shaped load pulses. Similar testing can be conducted on bound materials.

8.5.3 Bituminous Mixtures

Modulus of hot-mix asphalt (HMA) can be determined in several ways. The most common laboratory tests are the resilient modulus and the uniaxial frequency sweep.

Resilient modulus tests have been used by many researchers to measure the modulus of HMA. These tests can be performed either in compression or diametrically (ASTM D 4123). The following figures illustrate this test method's setup and results. Figure 2-13 shows the resilient modulus testing apparatus. Figure 2-14 shows the stresses applied to a confined specimen. Figure 2-15 shows the resilient modulus test cycle. Figure 2-16 shows the diametrical loading of HMA specimen for modulus testing.

The uniaxial frequency sweep test is very similar to the cyclic triaxial tests. The stresses and strains under sinusoidal loading and varying temperatures and loading frequency are measured and the dynamic modulus is determined. The dynamic modulus is an HMA input parameter in the AASHTOWare Pavement ME design process.

Several parameters affect the modulus of bituminous mixtures. The most important parameters are the rate of loading, temperature, and air void content.

Figure 2-13. Resilient Modulus Testing Apparatus.

Figure 2-14. Stresses acting on a triaxial specimen.

Figure 2-15. Resilient Modulus Test Cycle.

Figure 2-16. Diametrical loading of HMA specimen for modulus testing.

8.5.4 Field-based Measurements of Moduli

Several field-testing methods are available for determining the modulus of a pavement layer. The main methods used are either deflection-based or seismic-based. The falling weight deflectometer (FWD) is the most common field (structural) evaluation device used in Texas. The deflection measurements can be used in backcalculation methods to determine pavement structural layer stiffness, the subgrade elastic modulus, and the depth to stiff layer (bedrock). These are required inputs when using FPS 21 design.

‘Backcalculation’ is a mechanistic evaluation of pavement surface deflection basins generated by various pavement deflection devices. Backcalculation takes a measured surface deflection and attempts to match the value (to within some tolerable error) with a calculated surface deflection generated from an identical pavement structure using assumed layer stiffnesses (moduli).

The assumed layer moduli in the calculated model are adjusted until they produce a surface deflection that closely matches the measured one. The combination of known layer thicknesses and assumed layer stiffnesses that results in this match is then assumed to be near the actual in situ moduli for the various pavement layers.

The backcalculation process is usually iterative and normally run with computer software. Backcalculation guidelines are discussed later in Chapter 5, Section 4 (see “FPS 21 Modulus Inputs and Backcalculation Methodology”), in the manual.

8.5.5 Other Material Characterization Methods

Chapter 4, “Pavement Evaluation,” describes additional field and laboratory methods for characterizing material properties.

Anchor: #i10096648.6 Drainage Characteristics

Drainage characteristics should be noted during a visit to the project site. Items such as the general terrain drainage, the highway drainage (including cross slopes, condition of existing culverts, and ditch depth/capacity), and any existing internal pavement drainage features should be noted.

Another drainage item to consider is bridge-class drainage structures. The number of bridges and how the existing pavement terminates at the bridge ends is important to note. Also, note if the bridges have bridge approach (rigid pavement) slabs. The condition of the bridge end/approach slab and the approach slab/pavement interface conditions are of special interest where concrete pavement is present. These pavement interfaces often provide a location for surface runoff to enter the pavement structure and may lead to wash outs of fill material behind bridge head walls, MSE embankments, and rip-rapped slopes.

8.6.1 Internal (Positive) Pavement Drainage

Moisture intrusion into a pavement structure has been a known source of reduced service life since the earliest roads were constructed. The principles of drainage management for pavement structures have not changed radically since AASHTO published the 1986 Guide for Design of Pavement Structures.

In Vol. 2, App. AA of that reference, internal drainage systems are advocated particularly for “problem areas” as determined from experience and a drainage analysis of the particular project right-of-way. Federal-Aid Policy Guide’s supplemental materials, 23 CFR Part 626, stresses:

". . . inadequate subsurface drainage continues to be a significant cause of pavement distress, particularly in Portland cement concrete pavements." And “Where the drainage analysis or past performance indicates the potential for reduced service life due to saturated structural layers or pumping, the design needs to include positive measures to minimize that potential.”

Positive drainage measures are defined as permeable bases and the gathering and discharge system required for these bases. They are generally synonymous with internal or subsurface pavement drainage (underdrain) features. When internal drainage is contemplated for use within the pavement structure, the department philosophy since 1994 on conducting a full drainage analysis has been restricted to:

- Anchor: #XBSPELDH

- all rigid structures and full-depth HMA pavements that are 8.0 in. thick or greater Anchor: #NBHSEFXD

- where rainfall is 20 in./yr. or more, and Anchor: #AHFAOLRC

- average daily traffic (ADT) exceeds 7500 vpd.

The following is a list of exceptions:

- Anchor: #HDKXMABE

- The proposed design has given good performance in the past (under similar soil, environment, and traffic) and this performance can be documented. Anchor: #GSNEOIWH

- Adequate ditches cannot be constructed to collect water from the pavement structure due to right-of-way restrictions. A drainage system should not be constructed if it is susceptible to back flow from ditches or storm sewer during the 10-yr. flood. Anchor: #SAJVAXMH

- Future maintenance of the longitudinal edge drains cannot be accomplished. Anchor: #SYNTFLMX

- In urban areas where frequent utility work may be needed. Anchor: #XKRMIQGF

- When movement is expected in full-depth HMA structures due to swelling clay subgrade soils. Anchor: #ECLIKGVP

- Where fast track construction is required or where the subbase must carry traffic during construction. A discussion must be included to cover the need for fast track construction and traffic handling.

The department’s overall philosophy on pavement drainage design has been more focused on minimizing surface moisture infiltration or the effects of surface infiltration through construction and maintenance techniques such as constructing an adequate surface cross slope, maintaining proper ditch depth, using non-moisture susceptible materials, and aggressive use of seal coats and crack sealing, rather than on establishing internal drainage features.

Department Policy. Aspects of the department’s policy are evident in many ways, such as, establishing a non-erosive base beneath rigid pavements and establishing QC/QA density requirements and anti-stripping evaluation for HMA. A substantial concern has existed over the maintainability of the internal drainage systems, including clogging of the permeable layer with fines, crushing of the permeable layer during construction, clogging of edge drains through rodent activity or sedimentation, crushing of edge drains, etc. A clogged drainage system is worse than no drainage system; it can keep the pavement in a state of saturation for a prolonged period.

As stated above, there is potential for back-flow if ditches cannot be constructed with enough depth. However, there are occasions where positive pavement drainage may be considered a viable alternative, especially in cases where non-uniform cross sections exist or are planned. In particular, sections that have a “bath tub” nature where the outside edge of the structure is fairly impervious and will not allow lateral exodus of trapped moisture, positive drainage systems may be a good solution.

The case of retro-fitting edge drains on old rigid pavements with flexible pavement shoulders is one example. These structures tend to have a highly pervious longitudinal joint at the PCC-HMA interface that resists long-lasting maintenance solutions. An edge drain trenched into the shoulder at the interface with laterals to carry the water away from the structure can be effective in reducing or eliminating pumping under the slab. A similar situation can exist in flexible pavements widened using full-depth HMA or deep structures with impervious backfilled side slopes. Diligence in ensuring adequate compaction and thickness of pavement materials to support truck wheel loads above the retro-fitted drain is needed to prevent pavement failure at the lane/shoulder interface for traffic that may occasionally wander from the driving lane.

A typical retro-fitted edge drain system is shown below in Figure 2-17. An example of positive drainage using a permeable base layer is shown in Figure 2-18. Variations can exist where laterals will empty into a storm drainage system.

Figure 2-17. Retro-fitted Edge Drain.

Figure 2-18. Positive drainage using a permeable base layer.

Another major source of free moisture into the pavement structure is ground water. The department’s policy has been that ground water should be intercepted outside of the pavement structure to eliminate the impact of this source. This should be pursued when seepage from higher ground is a problem. Moisture migration from capillary action or vapor movements can be addressed using the drainage options pictured above.

‘Appendix AA’ of the 1993 AASHTO Guide and the Drainable Pavement Systems Participant Notebook for the FHWA Demonstration Project 87 (1992) are useful references for designing internal pavement drainage systems.

Other references: 1993 AASHTO Guide, NCHRP Synthesis 285 (2000), and the NCHRP Mechanistic-Empirical Pavement Design Guide (NCHRP Project 1-37A), ‘Appendix SS, Hydraulic Design, Maintenance, and Construction Details of Subsurface Drainage Systems.’

Cited references are available upon request from MNT – Pavement Asset Management.

Anchor: #i10098198.7 Evaluating Existing Pavement Condition

The District will take adequate measures to properly characterize the existing functional and structural condition of pavements scheduled for rehabilitation. Evaluating a pavement’s existing condition is necessary for any rehabilitation or reconstruction project as a means to determine the adequacy of past performance, failure mechanisms, and extent of rehabilitative effort necessary. Evaluations are conducted to determine both structural and functional characteristics and can involve both destructive and nondestructive tests and surveys.

Destructive testing involves boring or trenching into the existing structure with the goal of obtaining samples for further laboratory evaluation and to observe the in situ condition of the various layers.

Nondestructive tests and surveys are available to acquire data that can be reduced to structural properties, presence of moisture, degree of distress, friction properties, and smoothness. Nondestructive surveys can also serve as a screening tool to identify locations to perform destructive testing. Pavement evaluation is discussed in, Chapter 4 “Pavement Evaluation.”