Section 2: In-place Surface Recycling

Anchor: #i10072932.1 Hot In-place Recycling (HIR)

This rehabilitation technique is meant to address asphalt concrete surface distress and texture issues only; therefore, the underlying base layers must offer adequate support for both the HIR paving train and projected future traffic. Procedures are covered under Item 358 of the Standard Specifications.

The HIR process involves recycling the existing asphalt surface layer by heating, scarifying, and adding a recycling agent. There are three basic HIR processes:

- Anchor: #LXYJXQVV

- Recycling – heating, scarifying, rejuvenating, leveling, reprofiling, and compacting. Anchor: #VFIOOIIS

- Remixing – heating, scarifying, rejuvenating, mixing (adding virgin aggregate or new hot-mix), leveling, reprofiling, and compacting. Anchor: #QEFNDLMV

- Repaving – combines either recycling or remixing with an overlay of new HMA placed immediately after the recycled mixture. The new HMA layer is placed directly on the recycled layer, and both are compacted simultaneously.

A specialized train (shown in Figure 7-1) is used to heat the surface of the pavement to 200 - 350°F which allows the top 1 to 2 in. of material to be scarified, rejuvenated, remixed and replaced in a multi-step on-site process. Minor cross slope and aggregate gradation corrections can be made. Virgin hot-mix can also be added to correct the recycled asphalt pavement (RAP) shortcomings as in the case of the remixing process. Coring of the existing asphaltic concrete pavement (ACP) surface is necessary to determine the material properties of the existing asphalt pavement. This will allow for evaluation of any necessary adjustments to aggregate gradation to develop the required voids in mineral aggregate (VMA) and selection of the appropriate asphalt cement (AC) binder. Mix design must meet Item 358 requirements.

Pavements with delaminations, especially saturated delaminations, in the top 2 in. should not be considered for HIR projects. Also, the state of practice does not recommend pavements that have been rutted, heavily patched, contain fabric seals, excessively chip-sealed, or rubber chip-sealed as good candidate projects. The 2014 specifications cite a minimum surface temperature for commencement of HIR operations of 60ºF, or if the conditions are such that the roadway surface will reach the required temperature within 2 hr. of the beginning of placement operations. An additional overlay may be placed over the recycled surface if additional structural strength is needed, as in the case of the repaving process. An equivalent alternative strategy is to mill 1 in. of the existing top layer and place back 2 in. Refer to Item 340 for allowances of recycled products in the new 2-in. overlay.

Figure 7-1. Hot In-place Recycling Train.

Anchor: #i10076272.2 Cold In-place Recycling (Bituminous Layers Only)

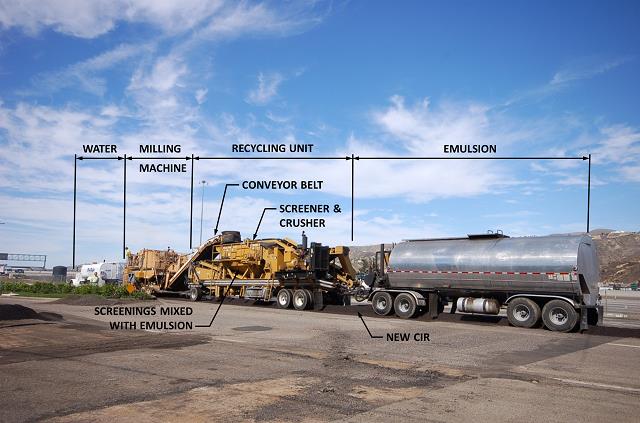

As with the hot in-place process, this rehabilitation technique is meant to address distress within the bituminous portion of the pavement structure, but can reach as deep as 4 to 6 in. Therefore, the base must also be sound, with repairs made to locations that have failed or show potential for failure. The process also involves a specialized train with a cold milling machine, crushing/screen unit, and mixing unit that is capable of reclaiming the old asphalt, crushing (screening and sizing) the RAP, and mixing the RAP with virgin aggregate (if necessary) and emulsion. Figure 7-2 shows a cold in-place recycling train. More recently, foamed asphalt has been used as a binding agent, replacing emulsion on some jobs in other states (Caltrans and others). Other additives, such as lime, fly ash and cement, may be used to improve moisture susceptibility and early strength properties. Coring of the existing ACP surface is necessary to determine the material properties of the existing asphalt pavement to properly design proportions of virgin aggregate, emulsion, and rejuvenator, if necessary. Cores are also inspected for the presence of variations in the pavement layers, delaminations, and whether voids are saturated. The industry does not recommend pavements that have been rutted, heavily patched, or excessively chip-sealed as good candidate projects. Typically, a seal coat or additional overlay will be required after adequate curing since the cold re-processed mix has higher void ratios and is more difficult to compact than hot-mix. Application of this procedure has been addressed through special specifications.

Figure 7-2. Cold In-place Recycling Train.