Section 2: Base and Subgrade Preparation

Anchor: #i10241302.1 Introduction

Pavement performance can be largely attributed to the care given in designing and preparing its foundation, which is comprised of the subgrade and base layers. Base and subgrade layers must provide adequate and moisture resistant strength that meets the design modulus, in addition to durability and stability.

Frequently, in situ soils and local base materials do not meet project-specific requirements. Texas also has some of the most expansive soils in the country, which cause distresses in many pavements around the state, and requires considerations beyond basic FPS design inputs to mitigate.

Currently, a large portion of pavement construction consists of rehabilitating existing roads. These roads frequently contain subgrade or base material layers that are inadequate for current or future traffic loading demands. Shortages of locally available high quality soil-aggregate resources are becoming more and more common statewide.

In order to achieve specified properties, subgrade, select fill, and base materials frequently require chemical treatment with additives such as lime, cement, fly ash, and asphalt. Each of these materials must be properly designed to determine the most appropriate additive and concentration to achieve the desired improvement.

Additive selection criteria can be found in the “Guidelines for Chemical Treatment of Soils and Bases in Pavement Structures.” This document also outlines the proper methodology of defining the goals for treatment and selecting, designing, and evaluating treated soils and base courses for pavement structures. In addition, this document provides some basic knowledge on the various treatment methods and the mechanism each treatment method employs. See Chapter 3 or contact MNT – Pavement Asset Management for more information.

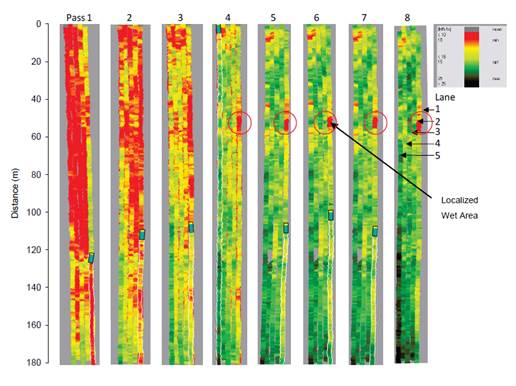

Anchor: #i10242432.2 Intelligent Compaction

Intelligent Compaction (IC) is an innovative approach for a continuous quality control process with the objective of achieving uniform and consistent compaction during the placement of soil and aggregate base materials. IC uses vibratory compactors instrumented with global positioning systems, an integrated stiffness measurement system, and real-time computer imaging feedback that plots coverage and compaction progress, allowing the roller operator to make timely tracking adjustments to ensure adequate/uniform compaction coverage. The technology has matured over the past several years to allow inclusion on most jobs for proof rolling. Contact MNT – Pavement Asset Management for more information.

Figure 6-1. Intelligent Compaction Operator’s Screen Displaying Relative Degree of Compaction.