Section 4: Rigid Pavement Design Process for CPCD

Anchor: #i10077854.1 Introduction

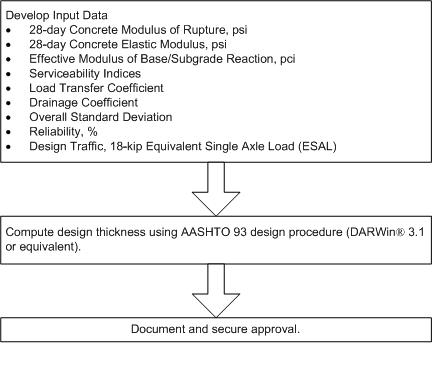

The following Figure 8-4 summarizes the CPCD design process.

Figure 8-4. CPCD Pavement Design Process.

Anchor: #i10077994.2 Input Values

The following input variables are needed for the AASHTO rigid pavement design procedure.

Anchor: #TUEQLRKO4.2.1 28-day Concrete Modulus of Rupture, Mr

The Mr of concrete is a measure of the flexural strength of the concrete as determined by breaking concrete beam test specimens. An Mr of 620 psi at 28 days should be used with the current statewide specification for concrete pavement design. If the engineer selects an alternate value for Mr, it must be documented with an explanation.

Anchor: #XIXUSOPU4.2.2 28-day Concrete Elastic Modulus

Elastic modulus of concrete is an indication of concrete stiffness. It varies depending on the coarse aggregate type used in the concrete. Although the value selected for pavement design could be different from the actual values, the elastic modulus does not have a significant effect on the computed slab thickness. A modulus of 5,000,000 psi should be used for pavement design. The use of a different value must be documented with an explanation.

Anchor: #GHEHMUXG4.2.3 Effective Modulus of Subgrade Reaction: k-value

The AASHTO Guide allows pavement designers to consider the structural benefits of all layers under the concrete slab. The guide also allows designers to consider the effect of loss of support of the underlying material due to erosion or deterioration. The slab support is characterized by the modulus of subgrade reaction, otherwise known as k-value.

A k-value of 300 psi/in. should be used in the CPCD design procedure with one of the stabilized base layer combinations listed below.

Field performance evaluations of concrete pavement have revealed that the use of a durable, stabilized, and non-erodable base is essential to the long-term performance of concrete pavement. If the base underneath the concrete slab does not provide good support, long-term pavement performance will be severely compromised, regardless of the concrete slab thickness.

The department recognized this and requires one of the following base layer combinations for concrete slab support:

- Anchor: #RAYKJITY

- 4 in. of hot-mix asphalt (HMA) or asphalt treated base (ATB), or Anchor: #LHQMRQCN

- a minimum 1 in. hot-mix asphalt bond breaker over 6 in. of a cement treated base. Use Item 276, Class L.

Approval from the Pavement Analysis & Design Branch of MNT – Pavement Asset Management Section is required for use of base layers other than those listed above.

Selection of CTB Class

To ensure long-term strength and stability of cement treated layers, sufficient cement must be used in the mixture. Item 276, “Cement Treatment (Plant-Mixed),” currently designates three classes of cement treated flexible base, based on 7-day unconfined compressive strength. Class M is intended for use with flexible pavements. Class L is intended for use with rigid pavements. Class N can be used if the district has successful long-term experience with other strengths.

Use of Bond Breaker

A bond breaker should always be used between concrete pavement and cement treated base. There have been several instances across Texas where excessive cracking and premature failures occurred when a concrete slab was placed directly on cement treated base. These problems occur because concrete slabs tend to bond directly to cement treated bases. This increases the chances for cracks in the base to reflect through the overlying slab. This also increases tensile stresses in the concrete slab due to temperature and moisture changes, resulting in higher chances of additional cracking.

TxDOT recommends a minimum of 1 in. asphalt concrete stress-relieving layer be used between cement treated base and the concrete slab. A polyethylene sheet is not recommended for use as a bond breaker, due to construction problems evident from past experience.

The subgrade is usually stabilized or treated with lime or cement to facilitate construction as well as to provide additional support to the pavement structure. Large volume changes in the subgrade resulting from moisture variations or other causes can cause the deterioration of concrete pavement. These volume changes in the subgrade should be minimized by appropriate means. Contact the Geotechnical, Soils and Aggregates Branch of CST for further assistance.

The subgrade/base should be designed 2 ft. wider than the concrete slab on each side to accommodate slipform pavement equipment.

If the engineer elects to use a "drainable base," then coordination with Geotechnical, Soils and Aggregates Branch of CST personnel is required. Refer to Chapter 2, Section 7, for an example of a typical drainable base system.

Anchor: #RIQKYLWG4.2.4 Serviceability Indices

For concrete pavement design, the difference between the initial and terminal serviceability is an important design consideration. An initial serviceability value of 4.5 and a terminal serviceability value of 2.5 are to be used in the procedure, which results in a difference of 2.0. Different values, if used, must be documented and justified.

Anchor: #EELJCKXS4.2.5 Load Transfer Coefficient

The load transfer coefficient is used to incorporate the effect of dowels, reinforcing steel, tied shoulders, and tied curb and gutter on reducing the stress in the concrete slab due to traffic loading. The coefficients recommended in the AASHTO Guide were based on findings from the AASHO Road Test.

The department requires the use of tied concrete shoulders, tied curb and gutter, or a widened lane, and the use of load transfer devices, so the load transfer coefficient to be used for CPCD design is 2.9.

Anchor: #RTLUBRIL4.2.6 Drainage Coefficient

The drainage coefficient characterizes the quality of drainage of the base layers under the concrete slab. Good draining pavement structures do not give water the chance to saturate the base and subgrade; thus, pumping is not as likely to occur.

The AASHTO Guide provides a table of drainage coefficients based on the anticipated exposure of the pavement structure to moisture and on the quality of drainage of the base layers. Higher drainage coefficients represent better drainage. The most credit is given to permeable bases with edge drains.

The department has not had much experience with positive drainage systems. As stated in Chapter 2, the department’s philosophy on this issue is to prevent water intrusion and pumping by using bases that are dense-graded, non-erosive, and stabilized. The department has had good performance with such bases, and it is believed that the bases recommended earlier in this section provide performance equivalent to the AASHTO ‘fair’ level of drainage.

Currently, drainage coefficients in Texas for non-erosive stabilized bases are based on the anticipated exposure of the pavement structure to water. “Table 8-3 Drainage Coefficients” shows the recommended drainage coefficients for Texas. The coefficients are selected based on the annual rainfall in the project area.

|

Annual Rainfall (in.) |

Drainage Coefficients |

|---|---|

|

58 – 50 |

0.91 - 0.95 |

|

48 – 40 |

0.96 - 1.00 |

|

38 – 30 |

1.01 - 1.05 |

|

28 – 20 |

1.06 - 1.10 |

|

18 – 8 |

1.11 - 1.16 |

|

NOTE: Higher drainage coefficients decrease the pavement thickness in the AASHTO procedure. |

|

Anchor: #BRCEUEQX

4.2.7 Overall Standard Deviation

Overall standard deviation accounts for both chance variation in the traffic prediction and normal variation in pavement performance prediction for a given traffic. The AASHTO Guide recommends values in the range of 0.30 to 0.40, with 0.35 being the overall standard deviation from the AASHO Road Test. Higher values represent more variability; thus, the pavement thickness increases with higher overall standard deviations. A value on the high end of the range is considered reasonable for Texas since it is believed that the inputs recommended for Texas are less accurate than the inputs determined at the AASHO Road Test. A value of 0.39 is to be used for CPCD design.

Anchor: #HVKWBEJN4.2.8 Reliability, %

The reliability value represents a "safety factor" with higher reliabilities representing pavement structures with less chance of failure. The AASHTO Guide recommends values ranging from 50% to 99.9%, depending on the functional classification and the location (urban vs. rural) of the roadway. Based on TxDOT's experience, a reliability of 95% should be used for rigid pavement with more than 5 million design ESALs; a reliability of 90% should be used for rigid pavement with 5 million or less design ESALs. If the engineer decides to use a different value, then it must be documented and justified.

Anchor: #XJKVVPLX4.2.9 Design Traffic 18-kip ESAL

The AASHTO Guide requires a prediction of the number of 18-kip ESALs that the pavement will experience over its design life.

The traffic projections for a highway project (in terms of ADT and one-way total 18-kip ESALs) are obtained from the traffic analysis report provided by TPP. This report is requested during the design phase of a project and, upon receipt, should be evaluated for reasonableness using guidelines discussed in Chapter 2, Section 8.

The predicted 18-kip ESALs is multiplied by a lane distribution factor (LDF). Table 8-4 lists the lane distribution factors. This factor represents the percentage of the total one-way 18-kip ESALs that could be expected in the design lane. The design lane is the lane that will carry the most traffic. Usually, it is assumed that the outer lane of a highway with two lanes in each direction carries the most traffic. For a three-lane facility, the middle lane is assumed to carry the most traffic. Traffic distribution in urban areas is somewhat more complex due to merging and exiting operations, but the same assumptions could apply.

|

Total Number of Lanes in Both Directions |

LDF |

|---|---|

|

≤ 4 |

1.0 |

|

6 |

0.7 |

|

≥ 8* |

0.6 |

|

*Unless field observations show otherwise |

|