Section 3: Concrete Plant Operation

Anchor: #i10145623.1 Introduction

A batch plant is the concrete mix plant where the aggregates, cementitious materials, chemical admixtures, and water are metered and combined together to produce hydraulic cement concrete. A batch of concrete is the amount of material mixed at one time. The batch plant can be a commercial concrete batch plant or a temporary batch plant brought in and assembled by the contractor near the paving site. On large concrete paving projects, most contractors choose to mix their concrete using their own temporary batch plant. This is because commercial batch plants are usually too small to produce the large amount of concrete needed for a concrete paving project.

Common methods of mixing concrete are:

- Anchor: #KBKWMKSN

- central-mixed, Anchor: #OTXDMOYP

- shrink-mixed, Anchor: #VBFXIKRL

- truck-mixed, Anchor: #NHOFUADP

- volumetric mixer-mixed, or Anchor: #AFOKRCDW

- hand-mixed.

Volumetric mixer-mixed and hand-mixed concrete are rarely used for concrete pavement construction and are not covered in this document. The other three mixing operations are described below.

Anchor: #i10070043.2 Central-mixed Plants

Central-mixed concrete is batched and completely mixed in a stationary mixer at the plant site. A central-mixed concrete plant completely mixes concrete before discharging it into haul vehicles. Central-mixed plants are sometimes referred to as wet batch plants. Figure 9-1 shows a diagram of central-mixing plants. About 20% of the concrete plants in the US use a central mixer. Principal advantages of the central-mixing plants include the following:

- Anchor: #YVFYSNXU

- higher production capability, Anchor: #KYWTVLMO

- better concrete quality control and consistency, and Anchor: #YSLJRULO

- reduced wear on the truck mixer drums.

Figure 9-1. Central-mixing plant.

In this central-mixing plant, aggregates (coarse and fine) are fed by conveyer belts from the left side. Cementitious materials, water, and chemical admixtures are supplied from the right side. Once all the ingredients are put into the mixer, they are mixed thoroughly and dumped into the trucks.

Accurate proportioning or batching of these materials per approved mix design is essential to producing concrete with satisfactory properties. The first step to achieve proper proportioning is to have all the weighing and measuring equipment properly calibrated.

Concrete materials are batched in three groups. One group is the aggregate group, and another is the cementitious materials group. These materials are either weighed individually or cumulatively. Water and admixtures comprise the last group. In most current central-mixing plants, the batching is done by computerized control system as shown in Figure 9-2.

Figure 9-2. Most batch plants are computerized.

Consistency of the concrete is greatly affected by the amount of water in the concrete. The accurate estimate of moisture content of the coarse and fine aggregate and proper batch water content adjustment is critical to the production of consistent concrete. In normal operations, moisture contents of fine aggregates are evaluated using moisture probes located in the weigh bins. Figure 9-3 shows a typical moisture probe used for fine aggregate.

Figure 9-3. Moisture probe for aggregates.

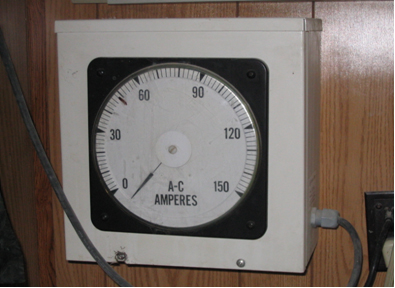

The amp meter in a central-mixed plant provides an indication of concrete mix consistency (see Figure 9-4). The amp meter is sometimes called the slump meter. Care must be taken when using this meter to control the mix consistency, since the amp meter reading is an indirect indicator of the consistency, which is derived from the correlation between consistency and electrical current needed to rotate the mixer.

Figure 9-4. Amp meter for workability.

The first step in the sequence of concrete production is charging the mixer. Charging the mixer consists of transferring all of the weighed or measured materials from weigh hoppers and silos into the central-mixer. Aggregates are ribbon loaded on conveyer belts. Initial blending takes place on the feed belt. This initial blending enhances mixer performance. Specific charging sequences vary.

Materials are blended in approximate proportions as they enter the mixer. One batch of concrete is being mixed while another is being batched. These operations occur simultaneously.

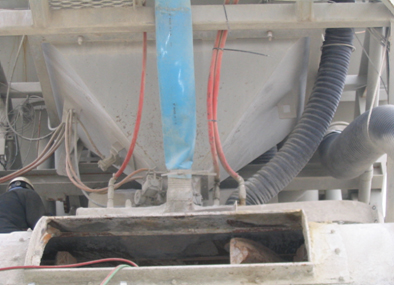

It is important that admixtures are not blended, since blending before discharging to the mixer can create undesirable interactions. Shown in Figure 9-5 are three orange hoses that feed admixtures. The big blue tube is the water supply line, which is diverted to both sides. Therefore, admixtures are not blended directly with each other; rather, they are blended with water first.

Figure 9-5. Water and admixture supply system.

The blades or paddles and the mixing action of a central-mix drum are quite different than a truck mixer, where there is little folding action compared with that in a stationary mixer. See Figure 9-6 for an illustration of the inside of a central-mix drum.

Figure 9-6. Paddles are shown inside a central mix drum.

Although a large variety of central plant mixers have been used over the years, the large tilting drum mixer is most popular. An example of a tilting drum mixer is shown in Figure 9-7.

Figure 9-7. Tilting drum mixer.

Mix times are dependent on rated capacity and speed of rotation of the mixer. Concrete should be mixed until a uniform mass is attained. Mixer performance can be tested in accordance with "Tex-472-A, Uniformity of Concrete," to indicate the mix uniformity.

Central-mixed concrete is transported in non-agitating trucks, truck mixers, or agitating trucks. In most of TxDOT’s concrete paving projects, contractors prefer non-agitating (dump) trucks for the efficiency. Figure 9-8 illustrates the charging of concrete into a dump truck.

Figure 9-8. Discharging concrete into a dump truck.

When non-agitating trucks are used to haul the concrete, the haul distance should not be far. Transporting concrete in dump trucks over a long distance can cause segregation and non-uniform consistency due to bleeding and setting.

After dumping the concrete, the truck bed needs to be washed out to the point where no clumps of concrete remain in the corners of the bed (see Figure 9-9). If concrete is allowed to build up in the corners of the bed, the clump becomes big and hard, and will break loose from the bed when the truck is dumping a load of concrete.

Figure 9-9. Rinsing truck between deliveries.

Anchor: #i10072343.3 Shrink-mixed Concrete

Shrink-mixed concrete is used to increase the truck’s load capacity and retain the advantages of truck-mixed concrete. In shrink-mixed concrete, concrete is partially mixed at the plant to reduce or shrink the volume of the mixture, and mixing is completed in transit or at the jobsite. This type of concrete is rarely used for TxDOT projects.

Anchor: #i10072473.4 Truck-mixed Concrete

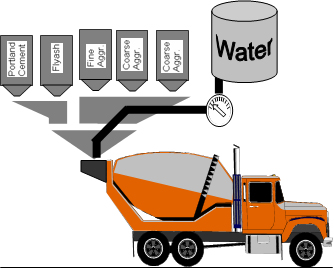

In truck-mixed concrete, all of the ingredients are charged directly in the truck mixer. In truck-mixed concrete or “dry batch” operation, as it is sometimes called, the batches are measured by the plant operator and charged from the weigh hoppers directly into the truck mixers for mixing. The plant operator is responsible for accurately batching the concrete in the proper and pre-determined sequence.

Sequences for charging truck-mixers are more critical than those for central mixers. Figure 9-10 illustrates this process. The first ingredients into the drum are usually a portion of the water and a portion of the coarse aggregate. The water is shut off and aggregates and cementitious materials are ribboned together until all of the cementitious material is in the drum. A final portion of water is added with the last of the aggregates to clean and wash any cementitious material clinging to the hoppers, rear fins, and chutes.

Figure 9-10. Truck-mixed or dry batching of concrete.

One of the problems when the proper batching sequence is not followed is so-called “head packs.” A head pack occurs when sand or sand and cementitious material packs in the head of the drum and remains lodged in the head without being mixed into the concrete. Typically, head packs will be about 12 to 24 in. thick. Head packs are difficult to detect because they break up after approximately half of the concrete has been discharged. Head packs are principally responsible for sand streaks, which occur in the final three-quarters of the discharge.

Once the batching is complete, generally the truck mixer driver completes the mixing in the yard. This allows the driver to examine the mix and determine if it is acceptable prior to leaving the batch plant site. When the mix is correct at the plant, it will most likely be correct when it arrives at the job site.

The truck mixer is equipped with a revolution counter and slump meter as shown in Figure 9-11. The driver is capable of estimating the slump to within 1/2-in. This meter is used for estimating only. The slump is still measured per the project specifications.

Figure 9-11. Slump meter mounted in the mixing truck.

It is necessary to rinse off the rear fins of the mixer between loads and wash and discharge the entire mixer only at the end of the day. Figure 9-12 illustrates the washing of the mixer drum.

Figure 9-12. Washing the mixer drum.

Concrete mixed in a truck mixer is transported to the jobsite at agitating speed. Between each load of concrete, no clumps of concrete should remain on the paddles or fins. Figure 9-13 shows examples of concrete clumps. If concrete is allowed to build up, it will eventually break loose from the drum when a load of concrete is discharged.

Figure 9-13. Large clumps of concrete.