Section 5: Plant Operations

HMA production is the first step in construction of HMA pavement layers. The basic purpose of an HMA plant is to properly proportion, blend, and heat aggregate, additives, and asphalt to produce an HMA that meets the requirements of the job mix formula (JMF) (Roberts et al., 1996). There are two basic types of HMA plans commonly in use today:

- Anchor: #GLXBWDAQ

- batch plant, Anchor: #EGOWQWSN

- drum mix plant.

Batch plants produce HMA in individual batches while drum plants produce HMA in a continuous operation. Each type of plant can produce the same types of HMA, and neither type of plant should impart any significant plant-specific HMA characteristics. The choice of a batch or drum mix plant depends upon business factors, such as purchase price, operating costs, production requirements, and the need for flexibility in local markets; both can produce quality HMA. This section gives a brief overview of batch and drum mix plants. More detailed information on plant operations can be found in:

Roberts, F.L., P.S. Kandhal, E.R. Brown, D.Y. Lee, and T.W. Kennedy. 1996. Hot Mix Asphalt Materials, Mixture Design & Construction. National Asphalt Pavement Association Research and Education Foundation. Lanham, M.D.

Transportation Research Board (TRB). 2000. Hot-Mix Asphalt Paving Handbook 2000. Transportation Research Board, National Research Council. Washington, D.C.

Anchor: #i10888465.1 Batch Plants

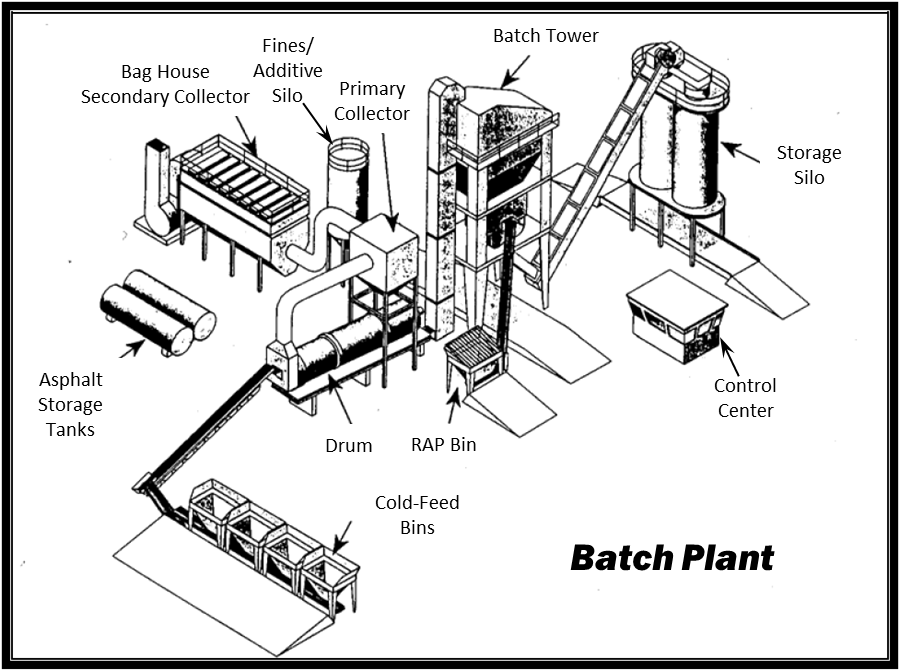

Batch plants, which produce HMA in individual batches, are the older of the two types of HMA production facilities. HMA was originally made in batches; it was not until the 1970s that drum plants became a popular HMA production option. Batch plants are not widely used in the United States, and the vast majority of newly manufactured plants are drum plants. This means that as older batch plants are retired, they are more than likely to be replaced by new drum plants, which can provide greater mobility and production capacity. Typical batch quantities range from 1.5 to 5 tons of HMA. Figure 6-11 shows the basic components of a batch plant.

Figure 6-11. Batch Plant. © Copyright 2006 University of Washington

Anchor: #i10899525.2 Drum Plants

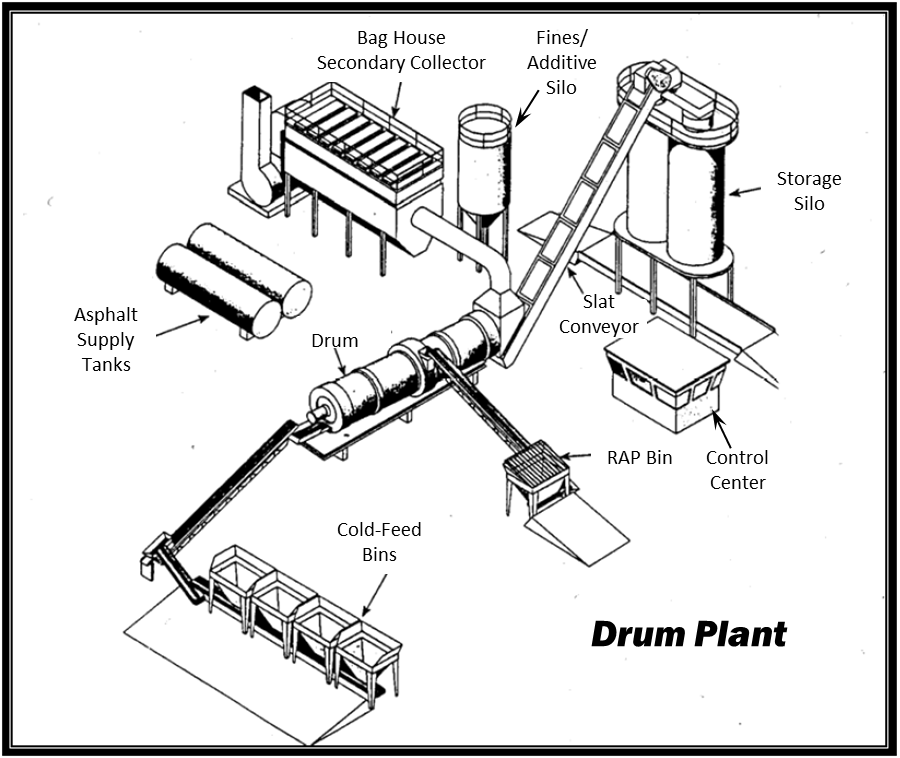

Drum plants, which produce HMA in a continuous manner, generally offer higher production rates than batch plants for comparable cost. Typical production rates for drum plants vary between about 100 tons/hr. up to over 900 tons/hr., depending upon drum design. Figure 6-12 shows the basic components of a drum plant and their function.

Figure 6-12. Drum Plant. © Copyright 2006 University of Washington