Section 2: Design Considerations

Anchor: #i1015460Economics

A wide spectrum of flood flows with associated probabilities occurs at the culvert site during its service life. The benefits of constructing a large capacity culvert to accommodate all of these events with no detrimental flooding effects are normally outweighed by the initial construction costs. Therefore, an economic analysis of the trade-offs should be conducted.

The initial cost is only a small part of the total cost over the lifetime of the culvert. Understanding how the culvert operates at discharges other than the design discharge can help you define some of the longer-term operational costs.

The cost of traffic detours can be the most important if factors such as the cost of emergency vehicle response time or detour distance and cost of operation per vehicle mile are considered, especially if there is a large average daily traffic rate.

Reduced to an annual cost on the basis of the anticipated service life, the long-term costs of a culvert operation include the following:

- Anchor: #IMLUENPT

- initial cost of the culvert Anchor: #TWBNWLQW

- cost of damage to the roadway Anchor: #DHIUBNQX

- cost of damage to the culvert and associated appurtenances Anchor: #PKJDHGSG

- cost of damage to the stream (approach and exit) Anchor: #GVWLLJOU

- cost of damage to upstream and downstream private or public property.

For minor stream crossings, the use of the Design Flood and Check Flood Standards table may preclude the need for a detailed economic analysis (see Chapter 4). A more rigorous investigation, such as a risk analysis may be needed for large culvert installations or when deviations from recommended design frequencies are indicated. Refer to Chapter 3 for discussion design by Evaluation of Risk assessment.

Anchor: #i1015554Site Data

The survey should provide you with sufficient data for locating the culvert and identifying information on all features affected by installation of the culvert, such as elevations and locations of houses, commercial buildings, croplands, roadways, and utilities. See Chapter 3 Process and Procedures and Chapter 4 Hydrology.

Anchor: #i1015566Culvert Location

Culvert location involves the horizontal and vertical alignment of the culvert with respect to both the stream and the highway. The culvert location affects hydraulic performance of the culvert, stream and embankment stability, construction and maintenance costs, and safety and integrity of the highway.

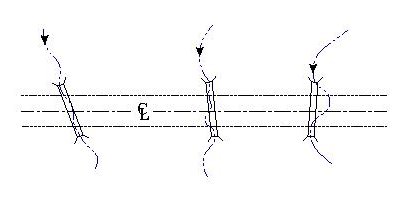

Ideally, you place a culvert in the natural channel (see Figure 8‑1). This location usually provides good alignment of the natural flow with the culvert entrance and outlet. It usually requires little structural excavation or channel work, which requires a USACE permit.

Figure 8-1. Culvert Placement Locations

Establishing the culvert’s vertical orientation is usually a matter of placing the upstream flow line and downstream flow line elevations of the culvert at the same elevations as the existing streambed.

In some instances, the upstream flowline may need to be lowered or raised. Lowering the upstream flowline can provide an improved hydraulic operation but may create maintenance problems due to a higher potential for both sedimentation and scour. However, lowering the upstream flowline can also decrease the slope of the culvert, thereby slowing the velocity and decreasing the potential for downstream scour.

The placement of the downstream flowline of the culvert at a level higher than the roadway embankment toe of slope should be avoided. Such a configuration results in a waterfall that increases the potential for erosion.

Sometimes, extending a culvert to accommodate a widened roadway requires changing the flowline slope at one or both ends. Such a configuration is called a broken back culvert. In some cases, a broken back configuration can be designed to reduce the outlet velocity by introducing a hydraulic jump inside the culvert.

Anchor: #i1015619Waterway Considerations

The installation of a culvert through a highway embankment may significantly constrict the floodplain. Therefore, pre-construction data should be collected to predict the consequences of the culvert alteration. Refer to Chapters 4, 5, and 7 for information on site surveys and data collection, hydrology, NFIP criterion, and channel properties.

The longitudinal slope of the existing channel in the vicinity of the proposed culvert should be determined in order to establish culvert vertical profile and to define flow characteristics in the natural stream. Often, the proposed culvert can be positioned at the same longitudinal slope as the streambed.

The existing channel must be evaluated for downstream obstructions that will affect the tailwater. Obstructions may include a narrowing of the channel or another roadway crossing or railroad crossing. Other phenomena which may affect the tailwater may be represented by a high roughness coefficient such as vegetation or excessive sinuosity, usually expressed as Mannings "n" (See Chapter 6, Roughness Coefficients). Other sources may include a decreasing channel slope, or water backed up from another source. The tailwater elevation will affect culvert capacity under outlet control conditions or may even drive a culvert into outlet control which may otherwise operate as inlet control.

The storage capacity upstream of (behind) the culvert may need to be considered, especially if the culvert is to be altered in a way that may increase the headwater.

The channel must be scrutinized downstream for adequate capacity, especially ifa culvert will be replaced with a larger barrel. Increased flow through the larger barrel could be perceived as causing flooding that had not occurred before. Although rare, the situation has been known to occur.

Anchor: #i1015680Roadway Data

The proposed or existing roadway affects culvert cost, hydraulic efficiency, and alignment.

Information from the roadway profile and the roadway cross section should be obtained from preliminary roadway drawings or from standard details on roadway sections. If the culvert must be sized prior to the development of preliminary plans, a best estimate of the roadway section must be developed, and the culvert design must be confirmed after the roadway plans are completed.

Roadway cross sections normal to the centerline are typically available from highway plans. However, the required cross section at the stream crossing may be skewed with reference to the roadway centerline. To obtain this section for a proposed culvert, combine roadway plan, profile, and cross-sectional data as necessary.

Preliminary dimensions and features of the culvert should become evident when the desired roadway cross section has been evaluated or established. The dimensions may be obtained by superimposing the estimated culvert barrel on the roadway cross section and the streambed profile, which will establish the inlet and outlet invert elevations. The elevations and the resulting culvert length are approximate since the final culvert barrel size must still be determined.

The roadway embankment represents an obstruction to the flowing stream, much like a dam. The culvert is similar to the normal release structure, and the roadway crest acts as an emergency spillway in the event that the upstream pool (headwater) attains a sufficient elevation. The location of initial overtopping depends on the roadway geometry. Generally, the location of overtopping (roadway sag) should coincide as closely as possible to the location of the majority of flood flow under existing conditions. Since the roadway centerline profile may not represent the high point in the highway cross section, location of the actual low point is critical.

Anchor: #i1015719Allowable Headwater

Energy is required to force flow through a culvert. Energy takes the form of an increased water surface elevation on the upstream side of the culvert. The depth of the upstream water surface measured from the invert at the culvert entrance is generally referred to as headwater depth.

The headwater subtended by a culvert is a function of several parameters, including the culvert geometric configuration. The culvert geometric configuration elevation consists of the number of barrels, barrel dimensions, length, slope, entrance characteristics, and barrel roughness characteristics.

Selection of a design flood and allowable design headwater elevation are restricted by the potential for damage to adjacent property, damage to the culvert and the roadway, traffic interruption, hazard to human life, and damage to stream and floodplain environment. Potential damage to adjacent property or inconvenience to owners should be of primary concern in the design of all culverts. By definition, the allowable headwater associated with the design discharge must also be below the roadway, that is, the roadway must be passable. Other possible critical elevations on the highway itself include edge of pavement, sub-grade crown, and top of headwall. In addition, the allowable change in headwater of the 1% AEP should be limited to 1.0 foot if at all practicable. For roadways encroaching on a FEMA-designated floodplain or Special Flood Hazard Area, refer to Chapter 5 for information on FEMA NFIP criteria and procedures.

Culvert installations under high fills may present an opportunity to use a high headwater or ponding to attenuate flood peaks. The possibility of catastrophic failure should be investigated prior to considering deep ponding because a breach in the highway fill could be quite similar to a dam failure:

Culverts should be located and designed for the least disruption of the existing flow distribution. Culvert headwater study should include verification that watershed divides are higher than design headwater elevations. If the divides are not sufficiently high to contain the headwater, if at all possible, culverts of lesser depths or earthen training dikes should be used to avoid diversion across watershed divides. In flat terrain, watershed divides are often undefined or nonexistent.

Anchor: #i1015776Outlet Velocity

The two basic culvert design criteria are allowable headwater and allowable velocity. Similar to the allowable headwater, the allowable outlet velocity is a design criterion that is unique to each culvert site. Allowable headwater usually governs the overall configuration of the culvert. However, the allowable outlet velocity only partially governs the overall culvert configuration but is the governing criterion in the selection and application of various downstream fixtures and appurtenances.

The velocity in the culvert is likely to be higher than that in the channel because the culvert usually constricts the available channel area. This increased velocity can cause streambed scour and bank erosion in the vicinity of the culvert outlet. There may also be eddies resulting from flow expansion. It is important to control the amount of scour at the culvert outlet because of the possibility of undermining of the headwall and loss of support of the culvert itself. Bank erosion may threaten nearby structures and may also disrupt the stability of the channel itself.

Scour prediction is somewhat subjective because the velocity at which erosion will occur is dependent upon many variables such as the characteristics of the bed and bank material, depth of flow in the channel and at the culvert outlet, velocity, velocity distribution, and the amount of sediment and other debris in the flow. Scour developed at the outlet of similar existing culverts in the vicinity is always a good guide in estimating potential scour at the outlet of proposed culverts.

Scour does not develop at all suspected locations because the susceptibility of the stream to scour is difficult to assess and the flow conditions that will cause scour do not occur at all flow rates. At locations where scour is expected to develop only during relatively rare flood events, the most economical solution may be to repair damage after it occurs.

At many locations, use of a simple outlet treatment (e.g., cutoff walls, aprons of concrete or riprap) will provide adequate protection against scour. At other locations, adjustment of the barrel slope may be sufficient to prevent damage from scour.

When the outlet velocity will greatly exceed the erosive velocity in the downstream channel, considerations should be given to energy dissipation devices (e.g., stilling basins, riprap basins). It should be recognized, however, that such structures are costly, many do not provide protection over a wide range of flow rates, some require a high tailwater to perform their intended function, and the outlet velocity of most culverts is not high enough to form a hydraulic jump that is efficient in dissipating energy. Therefore, selection and design of an energy dissipation device to meet the needs at a particular site requires a thorough study of expected outlet flow conditions and the performance of various devices. The cost of dissipation devices may dictate the design that provides outlet protection from low-frequency (high AEP) discharges and accepts the damage caused by larger floods. See Section 5 Velocity Protection and Control Devices.

Velocities of less than about 3 fps usually foster deposition of sediments. Therefore, 3 fps is recommended as a minimum for culvert design and operation.

Anchor: #i1015810End Treatments

End treatments serve several different purposes but typically act as a retaining wall to keep the roadway embankment material out of the culvert opening. Secondary characteristics of end treatments include hydraulic improvements, traffic safety, debris interception, flood protection, and prevention of piping (flow through the embankment outside of the culvert).

Anchor: #i1015836Traffic Safety

Cross-drainage and longitudinal drainage facilities are usually necessary in any highway project to relieve drainage from the natural phenomenon of runoff to the highway. However, due to their inherent mass and fixed nature, they can pose somewhat of a safety threat to errant vehicles and associated drivers and passengers.

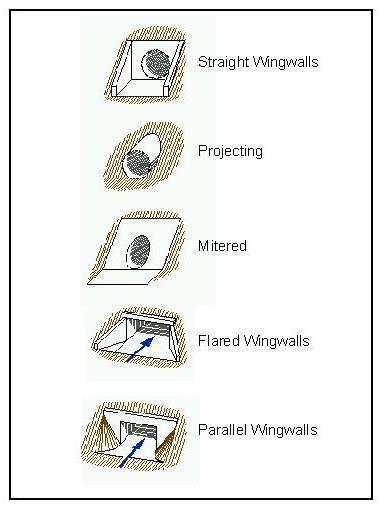

Figure 8-2 shows sketches of various end treatment types. The Bridge Division maintains standard details of culvert end treatments. For requirements and applications, see the Roadway Design Manual.

Figure 8-2. Typical Culvert End Treatments

Safety end treatment (SET) of a culvert provides a method of mitigating a less safe condition without interfering with the hydraulic function of the culvert. SETs such as those used with driveway and other small diameter culverts may be more hydraulically efficient by providing both tapered wingwalls and a beveled edge instead of using a mitered section. SETs for larger culverts that are not protected by a railing or guard fence use pipe runners arranged either horizontally or vertically.

Figure 8-3. Pipe mitered to conform to fill slope.

Figure 8-4. Pipe mitired to conform to fill slope.

Figure 8-5. End section conforming to fill slope

Figure 8-6. End section conforming to fill slope with pipe runners

Shielding by metal beam guard fence is a traditional protection method and has proven to be very effective in terms of safety. However, metal beam guard fence also can be more expensive than safety end treatment.

Generally, if clear zone requirements can be met, neither safety end treatment nor protection such as guard fence is necessary. However, some site conditions may still warrant such measures. See the Design Clear Zone Requirements in the Roadway Design Manual for more information.

Anchor: #i1015879Culvert Selection

Total culvert cost can vary considerably depending upon the culvert type. Generally, the primary factors affecting culvert type selection in Texas are economics, hydraulic properties, durability, and strength.

The following factors influence culvert type selection:

- Anchor: #WOCFRRNQ

- fill height Anchor: #MOCAXTUU

- terrain Anchor: #TQSGGERI

- foundation condition Anchor: #PFMXOSHU

- shape of the existing channel Anchor: #NEIHIIRJ

- roadway profile Anchor: #NKKOTMNB

- allowable headwater Anchor: #URMBRDRN

- stream stage discharge Anchor: #XKMEFFRD

- frequency-discharge relationships Anchor: #QYNCFPHF

- cost Anchor: #GYEBOQBE

- service life Anchor: #DTIWXFCM

- fish passage.

Culvert type selection includes the choice of materials to meet design life, culvert shapes, and number of culvert barrels. First, select a material that satisfies hydraulic and structural requirements at the lowest cost. Keep in mind that material availability and ease of construction both influence the total cost of the structure.

Second, choose culvert components that are readily available to construction contractors. Such material choices usually will assure better bid prices for the project.

Some commonly used combinations are as follows:

- Anchor: #RULYHADP

- Pipe (concrete, steel, aluminum, plastic): circular or pipe-arch and elliptical (CMP only). Anchor: #UEKJIMAN

- Structural-plate (steel or aluminum): circular, pipe-arch, elliptical, or arch. Anchor: #CIQWBTOC

- Box (or rectangular) (single or multiple barrel boxes or multiple boxes): concrete box culvert or steel or aluminum box culvert. Anchor: #DYLOLFMI

- Long span (structural-plate, steel or aluminum): low-profile arch, high profile arch, elliptical, or pear.

Culvert Shapes

Typically, several shapes provide hydraulically adequate design alternatives:

- Anchor: #AVXPTNQW

- Circular -- The most common shape used for culverts, this shape is available in various strengths and sizes. The need for cast-in-place construction is generally limited to culvert end treatments and appurtenances. Anchor: #LJXCFMMT

- Pipe-arch and elliptical – Generally used in lieu of circular pipe where there is limited cover or overfill, structural strength characteristics usually limit the height of fill over these shapes when the major axis of the elliptical shape is laid in the horizontal plane. These shapes are typically more expensive than circular shapes for equal hydraulic capacity. Anchor: #KEFLAWGK

- Box (or rectangular) -- A rectangular culvert lends itself more readily than other shapes to low allowable headwater situations. The height may be lowered and the span increased to satisfy hydraulic capacity with a low headwater. In addition, multiple barrel box culverts accommodate large flow rates with a low profile. Anchor: #QRGBXMPH

- Modified box -- Economical under certain construction situations, the longer construction time required for cast-in-place boxes can be an important consideration in the selection of this type of culvert. Pre-cast concrete and metal box sections have been used to overcome this disadvantage. Anchor: #VDHYHKVP

- Arch -- Arch culverts span a stream using the natural streambed as the bottom. As a result arch culverts serve well in situations where the designer wishes to maintain the natural stream bottom for reasons such as fish passage. Nevertheless, the scour potential and the structural stability of the streambed must be carefully evaluated. Structural plate metal arches are limited to use in low cover situations.

The terrain often dictates the need for a low profile due to limited fill height or potential debris clogging.

Anchor: #i1016029Multiple Barrel Boxes

Culverts consisting of more than one box are useful in wide channels where the constriction or concentration of flow must be kept to a minimum. Alternatively, low roadway embankments offering limited cover may require a series of small openings. In addition, the situation may require separating the boxes to maintain flood flow distribution. As a general recommendation, where a culvert consists of more than one barrel, shapes of uniform geometry and roughness characteristics should be used to maintain uniform flow distribution. Locations where debris flow may obstruct the culvert entrance may be better served with a clear span bridge.

Certain situations warrant placing boxes at various elevations. Placing one box at the natural stream flowline and placing additional boxes slightly higher is good practice for the following reasons:

- Anchor: #PSJXPXRQ

- the configuration does not require widening the natural channel Anchor: #PRPVWLVA

- the side boxes provide overflow (flood) relief when needed but do not silt up or collect debris when dry Anchor: #AQMWIJPA

- the minimal stream modification supports environmental preservation.

Design versus Analysis

Culvert design is an iterative process that starts with reasonable assumptions and culminates with a final selection of material, shape, and placement that satisfies the requirements of function and safety. Culvert analysis is a straight forward process that determines the functioning status of an existing culvert structure or a proposed design.

Culvert analysis includes determination of flow rates, velocities, and water surface elevations for the full range of probabilities (50%, 20%, 10%, 4%, 2%, and 1% AEPs) for both the existing and the proposed conditions. A complete list of the requirements for design can be found in the Documentation Reference Tables in Chapter 3.

Differences exist between computer programs. Simple culvert computer programs have limitations such as how they handle roadway overtopping and upstream momentum. More complex hydraulic programs are not so limited because they include features such as backwater calculations and more data input capabilities. Unless the culvert is hydraulically simple, the more complex hydraulic programs are recommended for use. For situations where the roadway is overtopped at the structure, the simplified computer methods become unstable when overtopping occurs. These errors can be critical when a FEMA NFIP analysis of water surface elevation is required. (See Chapter 5, Federal Emergency Management Agency (FEMA) National Flood Insurance Program (NFIP) Compliant Design Of Floodplain Encroachments And Minor Structures.)

Anchor: #i1016074Culvert Design Process

The culvert design process includes the following basic stages:

- Anchor: #NJXRIYBJ

- Define the location, FEMA NFIP status, orientation, shape, and material for the culvert to be designed. In many instances, consider more than a single shape and material. Anchor: #CRNMKXHE

- With consideration of the site data, establish allowable outlet velocity (vmax) and maximum allowable depth of barrel. Anchor: #VUFVRRVM

- Based upon subject discharges (Q), associated tailwater levels (TW), and allowable headwater level (HWmax), select an overall culvert configuration -- culvert hydraulic length (L), entrance conditions, and conduit shape and material to be analyzed. Anchor: #AADHPKFH

- Determine the flow type (supercritical or subcritical) to establish the proper approach for determination of headwater and outlet velocity. Anchor: #HPWICJDV

- Determine the headwater elevation and outlet velocity. Anchor: #WQSHHNSE

- Adjust slope or shape for excessive outlet velocity if necessary. Check effect on headwater elevation. Anchor: #DLLODJLV

- Continue to adjust configuration until headwater elevation and outlet velocity are within allowable limits. It may be necessary to treat any excessive outlet velocity separately from headwater and control by other means such as velocity controls.

Design Guidelines and Procedure for Culverts

The flow charts of Figure 8‑7 and Figure 8‑8 can guide the hydraulic designer in computing for the vast majority of culvert design situations.

Figure 8-7. Flow Chart A - Culvert Design Procedure

Figure 8-8. Flow Chart B - Culvert Design Procedure (cont.)

The following is a step-by-step culvert design procedure for a standard culvert configuration , i.e. straight in profile with one or more barrels of equal size. Each of the configurations considered in the iterative process of design process influences a unique flow type. Each new iteration requires a determination of whether there is inlet or outlet control.

1. Establish an initial trial size. The trial size may be picked at random or judiciously, based on experience. However, one convenient rule-of-thumb is to assume inlet control and proceed as follows: Determine the maximum practical rise of culvert (Dmax) and the maximum allowable headwater depth (HWmax). Determine a trial head using Equation 8-1.

Equation 8-1.

where:

- Anchor: #RTLORDHF

- h = allowable effective head (ft. or m) Anchor: #LBXGIPNB

- HWmax = allowable headwater depth (ft. or m) Anchor: #GJDSSXNJ

- Dmax = maximum conduit rise (ft. or m).

Use Equation 8-2 (a form of the orifice equation) to determine the required area, A, for the design discharge, Q. This assumes an orifice coefficient of 0.5, which is reasonable for initial estimates only.

Equation 8-2.

where:

- Anchor: #QXYYPDWP

- A = approximate cross-sectional area required (sq.ft. or m2) Anchor: #GLKTEEMX

- Q = design discharge (cfs or m3/s).

Decide on the culvert shape:

- Anchor: #TRHALIVI

- A properly designed culvert has an effective flow area similar in height and width to the approach channel section so that approach velocities and through-culvert velocities are similar. Anchor: #EMXDGAJM

- For a box culvert, determine the required width, W, as A/Dmax. Round W to the nearest value that yields a whole multiple of standard box widths. Divide W by the largest standard span S for which W is a multiple. This yields the number of barrels, N. At this point, the determination has been made that the initial trial configuration will be N - S Dmax L, where L is the length of the barrel in feet. Anchor: #OTVNETEE

- For a circular pipe culvert, determine

the ratio of area required to maximum barrel area according to Equation

8-3.

Equation 8-3.

Round this value to the nearest whole number to get the required number of barrels, N. At this point, the determination has been made that the initial trial size culvert will be N - D L circular pipe.

Anchor: #SNTYUAML - For other shapes, provide an appropriate size such that the cross section area is approximately equal to A.

2. Determine the design discharge per barrel as Q/N. This assumes that all barrels are of equal size and parallel profiles with the same invert elevations. The computations progress using one barrel with the appropriate apportionment of flow.

3. Perform a hydraulic analysis of the trial configuration. Generally, a computer program or spreadsheet would be used. Nomographs and simplified hand methods should be used only for preliminary estimates. For the trial configuration determine the inlet control headwater (HWic), the outlet control headwater (HWoc) and outlet velocity (vo) using Flow Chart A shown in Figure 8‑7. Flow Chart A references Flow Chart B, which is shown in Figure 8‑8.

4. Evaluate the trial design. At this step in the design process, you have calculated a headwater and outlet velocity for the design discharge through a trial culvert configuration has been calculated.

- Anchor: #MIGIUVYG

- If the calculated headwater is equal to or is not appreciably lower than the allowable headwater (an indication of culvert efficiency), the design is complete. A good measure of efficiency is to compare the calculated headwater with the culvert depth D. If the headwater is less than the depth, the configuration may not be efficient. Anchor: #DGLIKTTY

- If the calculated headwater is considerably lower than the allowable headwater or lower than the culvert depth D, a more economical configuration may be possible. Choose the trial culvert configuration by reducing the number of barrels, span widths, diameter, or other geometric or material changes. Repeat the calculations from step 2. Anchor: #KWYGBDOW

- If the calculated headwater is equal to or is not appreciably lower than the actual headwater and the culvert is operating as inlet control, an improved inlet may be in order. Anchor: #PVPXNFUH

- If the calculated headwater is greater than the actual headwater, change the trial culvert configuration to increase capacity by adding barrels, widening spans, and increasing diameter. Repeat the calculations from step 2. Anchor: #LFFNODDM

- If the operation is not inlet control, then the culvert geometry design is complete. Anchor: #WJMRPEBK

- If the culvert is operating with inlet control, the possibility exists for improving the entrance conditions with the aim of reducing the overall cost of the structure. Investigate the design of a flared (or tapered) inlet and associated structure.Because of the cost of the improved inlet, make a careful economic comparison between the design with a normal entrance and the design with an improved inlet. Anchor: #RJCPUWUO

- Check outlet velocities against the predetermined maximum allowable for the site. The culvert for which the calculated headwater is satisfactory may have an excessive outlet velocity. Excessive velocities are usually caused by a steep slope or a computational error. The definition of "excessive" is usually an engineering judgment based on local and soil conditions, but as a general rule, anything over 12 fps is considered excessive.

Consider any required outlet control or protection device as part of the hydraulic design. It is normal for a properly designed culvert to have an outlet velocity that is greater than the natural stream velocity.

- Anchor: #QBMDVHLX

- Develop a hydraulic

performance curve using the procedures outlined in the

Hydraulic

Operation of Culverts section. An overall hydraulic performance

curve for the designed culvert indicates headwater and outlet velocity

characteristics for the entire range of discharges. At an absolute

minimum, the additional analysis of the 1% AEP discharge is required

for both the existing and the proposed conditions.

- Anchor: #AAYSGQCB

- The design can be completed if the results of the headwater and outlet velocity represent an acceptable risk and conform to FEMA NFIP requirements. (See Chapter 2 and pertinent parts of the Project Development Policy Manual for more details.) Anchor: #SVCOIQQD

- However, if any of the hydraulic characteristics are unacceptable, some adjustment to the culvert design may be in order.

Evaluate other culvert performance risks. Identify and evaluate the potential for increased impact associated with different flood conditions.